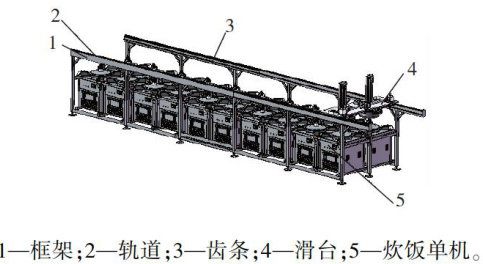

自动化米饭生产线的桁架机器人滑台优化设计

打开文本图片集

中图分类号:TP242.3 文献标志码:B 文章编号:1671-5276(2025)06-0232-07

Abstract:Trussrobotsarecommonlyemployed inthehandling processsofautomatedriceproduction lines.Toimprovethe eficiencyof themotordrivesystemand ensurehighdynamiccharacteristicsoftemaincarriageofthetrussrobot,twomethods, namelyaddingalighteningzoneandoptimizing key structural parameters,wereadoptedforthemulti-ojectiveoptimization designofthecariage.Halfofthedistancebetweenguiderails,spacing betweensliders,lengthoftheweightreduction zone, guiderailspecificationsandslidetablelength were takenasthevariablesforoptimization toexploretheirsignificacein influencingtheoptimizationobjectivewithorthogonalexperimentsandthroughrangeanalysis,varianceanalysisandfinite elementanalysis.Theslidetablewasoptimized usingtheBox-BehnkenDesignresponse surfaceanalysis method.Thesimulation results indicate that the optimized dynamic characteristics efficiency of the slide table increased by 14.02% ,the overall mass of the slide table decreased by 14.32% ,and the change in the first-order natural frequency after optimization could be neglected, asboth were at a relatively high level.

Keywords:slide table;finite element simulation;response surfaceoptimization;orthogonal experiment; lightweight design

0 引言

自动化米饭生产线在中央厨房中使用频繁,为提高人们就餐的效率和质量做出了一定的贡献[1]。(剩余7579字)