自适应技术在多工位机器人点焊中的应用研究

打开文本图片集

中图分类号:TP242.2 文献标志码:A 文章编号:1671-5276(2025)06-0214-04

Abstract:Regarding thequalitycontrolchallengescausedbythechangeclampingconditionssheets indiferentstationsand frequenttransformationwelding pointsrobots inthemulti-stationrobotspotweldingproductioncarfrontwheelcovers, thispaperanalyzesthethermodynamic processspot welding nuggetformationandthequalityproblems prone tooccur nmultistationoperations,andexplores‘howtouseadaptive technologytogeneratesamplecurvesand instantaneouslyadjustthe combinationcurrent,voltage,and electrode pressureparameters.Theopeningandclosing thecirculating coling water circuitf theservoweldinggunarecontrolldtoachievebalancedcontrolheatgrowthduringthespotweldingprocess,andthe electrode presure isadjusted tohavestcontact,soas toreducedefectssuch asspater,deformation,andfalse weldingand ensure the stable quality spot welding the front wheel cover.

Keywords:robot;multi-station spot welding;dynamic adjustment;sample curve;heat growth

0 引言

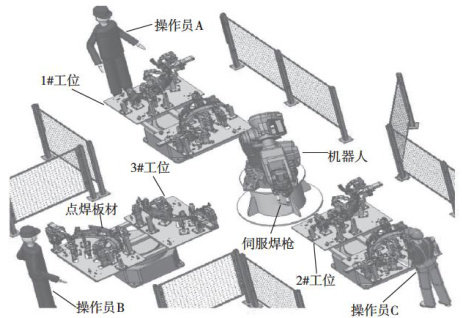

为适应汽车制造向轻量化发展的趋势和快速生产的节奏,采用多工位机器人点焊进行汽车钣金件大批量制造已经成为广泛应用的生产模式。(剩余5311字)