汽车零部件尺寸公差的统计过程控制应用分析

打开文本图片集

中图分类号:U463.6 文献标识码:A 文章编号:1003-8639(2026)01-0146-03

Statistical Process Control (SPC) Application Analysis ofDimensional TolerancesforAutomotive Parts

Chen Meng, Wang Jing (School of Modern Technology,Nanyang Artsand Crafts Vocational College,Nanyang , China)

【Abstract】 The automotive manufacturing industry has extremely strict requirements for the control accuracy of component dimensionaltolerances.Statistical Process Control(SPC)isthecore toolforachieving thisgoal.However, in modernautomotive component production practices,traditional SPC methods face numerous chalenges.Geometric Dimensioningand Tolerancing (GD&T)data oftenexhibitnon-normal distribution characteristics,the flexible production modeof multiple varietiesandsmallbatchesleads to insuffcientsamplesize,andtheautocorelationofhigh-frequency automated measurementdata allseriously weaken the monitoring efectivenesof standardcontrolcharts andtheaccuracy of process capability asessment. Therefore,this article proposes optimized SPC application strategies for special scenarios such assmal-batch production,detection of minute deviations inprecision machining,andreal-time monitoring ina digital environment.

【Key words 】automotive parts;dimensional tolerance; statistical process control

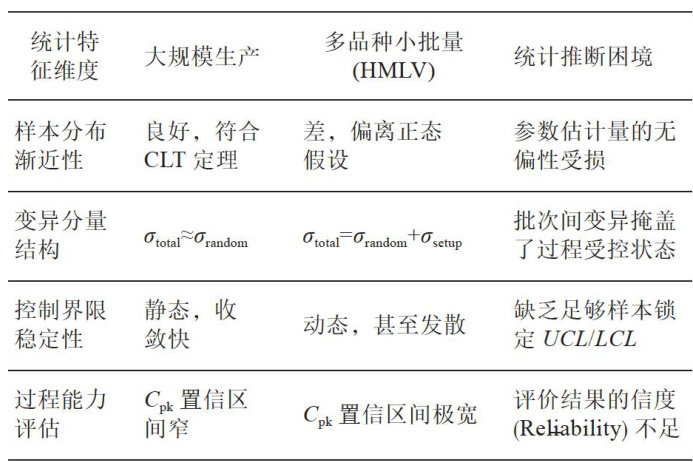

1现行统计过程控制在零部件生产中的应用难点

1.1形位公差数据的非正态分布特性带来的挑战

在汽车动力总成及底盘系统的精密制造中,位置度、平面度及同轴度等形位公差(GeometricDimensioningandTolerancing,GD&T)是衡量零部件几何精度的关键指标。(剩余4179字)