镍基高温合金蜂窝磨削加工毛刺优化研究

打开文本图片集

中图分类号:TG580.6 文献标志码:B 文章编号:1671-5276(2025)05-0079-05

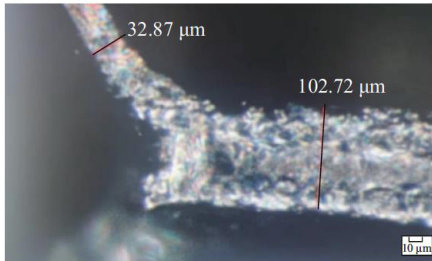

Abstract:To improve the grinding qualityof nickel based superalloy honeycomb,a comparative studywasconductedon theinfluenceof grinding parameters and whel structure onburrsize under conventional grinding and ultrasonic assisted grinding.The research results show that compared with ordinary grinding,ultrasonic asisted grinding can ffectively reduce the burr sizeof nickel-based superally honeycomb,especiallyfor welding edges.Compared to white corundum grinding wheel,employing ceramic bond CBN grinding wheelscan achievesmaler burr size. Through grinding experiments,optimized process parameter is obtained.

Keywords:ultrasonic assisted grinding;superalloy;honeycomb;burr

0 引言

翻边和毛刺,降低发动机汽封效果,毛刺脱落会进一步降低发动机的安全性及使用寿命[11-12]。(剩余5672字)