往复运丝电火花线切割加工FGH96试验研究

打开文本图片集

中图分类号:V263 文献标志码:A 文章编号:1671-5276(2025)05-0021-06

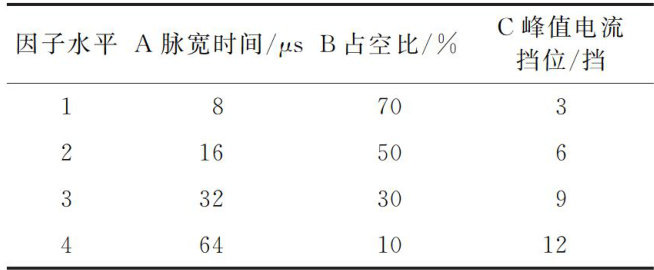

Abstract:The experimenton the reciprocating wire electrical discharge machining (WEDM) powder superally FGH96 was carried out to study the influence processparameters such as pulse width,duty cycle and peak current over machining eficiency,surface roughnessand recast layer thickness,and optimize a parameter combination 8 μs in pulse width, 10% in duty cycle and 12 in peak current level.On this basis,the change working fluid conductivity was used to simulate the influence working time the working fluid. The experimental results show that the working fluid needs to be replaced when its conductivity is increased to about 5.27mS/m . The machining experiments fir-tree slot andthe analysis onthe machining accuracyandtherecast layer thickness indicate that the recast layer thicknessat the top tooth is lessthan that attooth sideand tooth root,which preliminarilyverifies theapplicabilityreciprocating WEDM in rough machining turbine slots.

Keywords:WEDM;powder superalloy;orthogonal test;recast layer;turbine slot

0 引言

材料直纹构件的加工。(剩余6111字)