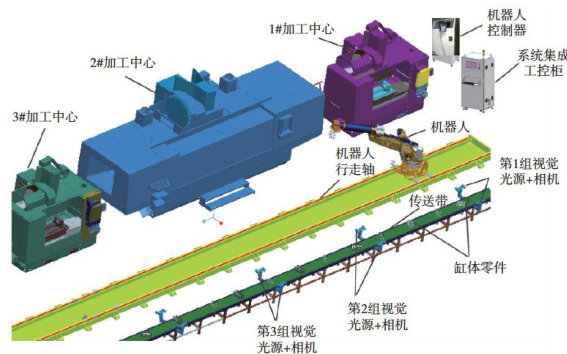

视觉跟踪在数控加工智能产线中的应用研究

打开文本图片集

中图分类号:TP242.2 文献标志码:A 文章编号:1671-5276(2025)03-0121-05

Research on Application of Visual Tracking in Intelligent Production Line of CNC Machining

HU Weifeng,HAN Wei,YAN Jian,LIU Jianguang

(School of Mechanical Engineering,Guangzhou City Universityof Technology,Guangzhou 5108Oo,China)

Abstract:Concerning theknow-howof robotsaccurately grasping partsrandomlyand disorderlyplacedontheconveyor belt duringtheoperationofflexibleCNCmachining production lines forautomotiveengines,thevisual control position trackigof FANUC visionsystemandthetechnical methodsofrobotrapid positioningand grasping of parts were studied.The proces of generatingvisual inspectionimagedataforparts placedindisorderontheconveyorbeltthroughmultiplecamerasandthe method of zeropointcalibrationand imagingparameterseting forthevisual systemcamera wereanalyzed.TheFANUCmacroprogram wasused tofittheimagingdataof twocamerasandgenerateapartpositioncordinatesystem,andthepositionoffsetdataof randomlyplacedpartswasdeterminedbycomparingandcalculating thestandard positioning template,so thattherobot coordinate system tracking,gripperposition adjustment,and part grasping program were developed,which improves the accuracy and reliability of CNC machining production line positioning.

Keywords:inteligent production line;robot;vision calibration;coordinate tracking;ofset compensation

0 引言

为了提高汽车制造企业的生产效率和智能化水平,在大批量的汽车发动机缸盖、缸体和减速箱盖等铝合金零件的柔性数控加工过程中,正在推广使用机器人自动上下料的方法,将传送带上的零件抓取送入或取出机床工作台。(剩余5014字)