6082铝合金高速搅拌摩擦焊温度场的数值模拟

打开文本图片集

中图分类号:TG453.9 文献标志码:A 文章编号:1671-5276(2025)03-0116-05

Numerical Simulation of Temperature Field in High-speed Friction Stir Welding of 6082 Aluminum Alloy

SHI Yuji, WU Kai

(School of Mechanical Engineering,Nanjing Universityof Scienceand Technology,Nanjing 21Oo94,China)

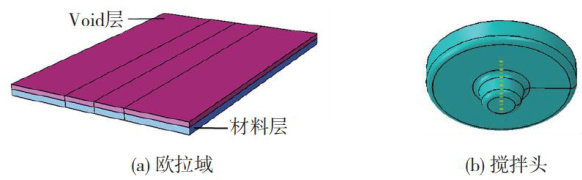

Abstract:BasedontheCoupledEulerian-Lagrangianmethod,athree-dimensionalfullythermodynamicallycoupledfinite elementmodelof high-speedfrictionstirweldingof6O82aluminumaloywasestablished,andtheresultswerecomparedwith thevaluesobtainedfromthetesttoverifytheaccuracyof themodel.Thetemperaturefeldofthe welding processwasstudied by numericalsimulation,andtheinfluencelawofthestirring toolrotationspeedandwelding spedonthetemperaturefieldwas analyzed.Theresultsshowthat thetemperaturefielddistributioninthestableweldingstageofhigh-speedfrictionstir welding presentsanasymmetric situation,with thetemperatureon the forwardside being higherthanthatonthe backward side,the temperaturebehindthestiring tolbeinghigherthanthatahead,andthetemperatureontheshaftshoulderandthebottom surfaceofthepinbeing higherthanthatonthesideof thepin.Asthestiring toolrotationspeed increases,the temperatureof the whole processof high-speed stirfriction welding increases;the welding speed increases,the inserting and preheating stage remainsunchanged,and the temperature of the stable welding stage decreases.

Keywords:high-speed friction stir welding;6O82 aluminum alloy;temperature field;numerical simulation

0 引言

搅拌摩擦焊(frictionstirwelding,FSW)是英国焊接研究所在1991年发明的一种新型固相焊接技术[1]。(剩余6411字)