基于数值模拟分析汽车发动机齿轮应力及模具磨损

打开文本图片集

中图分类号:U464.13 文献标识码:A 文章编号:1003-8639(2025)06-0158-03

BasedonNumerical Simulationof the Stress of Automotive Engine GearsandtheAnalysisof MoldWear WangHonglei,Li Xiaozhan

(Shangqiu Instituteof Technology,School of Mechanical Engineering,Shangqiu 476ooo,China)

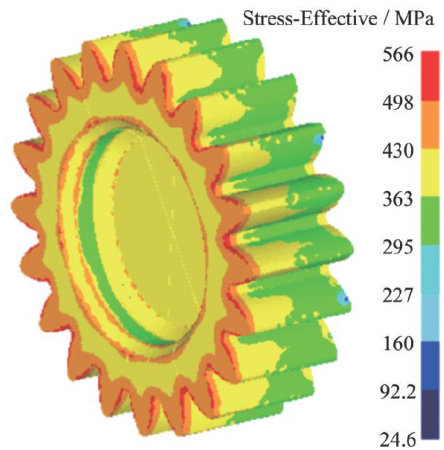

【Abstract】Through numerical simulation methods,thisarticle systematically analyzes the stress distribution and mold wear characteristics of automotive engine gears during the forging process.Based on the finite element analysis technology,theequivalent stress(up to566MPa)and strain concentrationareas(such as thetooth root)during the closeddie forging processof gears were simulated toreveal thecorelation between stressconcentrationand forging defects.Combining the mold designprinciples(precision,durability,and maintainability),optimize thematerial selection(high-speed stee,hard ally),structuraldesign(uniform force distribution),and manufacturing processes (electrical dischargemachining,wirecutting).Theresearch significantly improves theservice lifeof themoldby reducingthe forging speedandadjusting the mold parameters tocontrol the mold wear within O.Ooo30lmm.This achievement provides theoreticalbasisand technical supportfor theeficient manufacturingof enginegearsand the servicelife extension of molds.

【Key words】 engine gear;stress simulation analysis;strain simulation analysis;mold wea

1发动机齿轮模具的设计原则

1.1 精确性

齿轮作为发动机的核心部件之一,其设计和制造的品质直接关系到发动机的性能和寿命,齿轮在发动机中扮演着传递力量、密封气缸和散热等多重角色,因此,它的形状、尺寸和材料的选择都必须经过严格的计算和测试,而这一切的基础,就是齿轮模具的设计,所以保证模具的精确性至关重要[1-2]

1.2 耐用性

作为现代工业生产必不可少的核心部件,齿轮模具在高温、高压的工作环境下承担着十分重要的作用,要求齿轮模具能够在这种条件良好的环境下稳定且高效率地运行,就必须拥有良好的耐磨、耐腐蚀和不形变的能力。(剩余2846字)