皮带式青贮圆草捆打捆机打捆室设计与试验

打开文本图片集

中图分类号:S225;TP242.6 文献标识码:A 文章编号:2095-5553(2025)07-0247-06

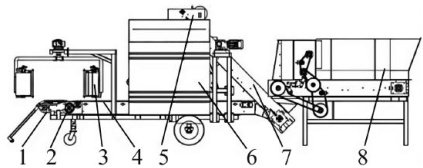

Abstract: To address common issues with existing silage round baling machines in China,such as material scatering, frequentblockagesatthefeedinlet,lowbalingdensity,andhighfailurerates,thisstudypresentsthedesignofabelttype baling machine.The machine consisted of a primary silo,a secondary upper silo,a baling chamber,a mesh device,a blanking and recycling unit,a film wrapping system,a wrapping table,a film-cuting tool holder,as well asintegrated electronic control systemandahydraulic system.First,theoretical calculations and3D parametric modeling were employed to carry out the dynamicanalysisand structural design of the baling chamber.Next,the material baling mechanism was studied in depth,witha focus on the force conditions acting on the grasscore andbaleduring the three keystages:core formation,belt deformation,andbaleroling.Finally, using silage corncrushedmaterial asthe test subject,a field trial was conductedat a planting base in Gansu to evaluatehow variousbaling parameters affect bale density.The results showed that under optimal conditions where baling pressure was 0.72MPa ,belt speed was 1.4m/s ,and feeding rate was 3.4kg/s ,thebaling density reached (204号 733kg/m3 ,which falls within the standard range for silage corn crushing material (730-740kg/m3⋅ .Thebaling efficiency achieved was ⩾50 bales per hour. This research provides both theoretical and empirical support for thedesignand optimization of baling machines in China,thereby contributing toimproved performance and reliability in silage baling operations.

Keywords:belt binding machine;silage corn;forming mechanism;bundle density;feed amou:

0 引言

圆捆机是机电液技术紧密配合的智能化农机,用户可通过手机或触摸屏监测机具作业过程中的各种参数,也可远程调节喂料速度、打捆压力、草捆直径以及裹膜参数等,实现饲料豆科牧草、禾本科牧草、灌木类牧草、农业废弃物等物料的打捆裹包。(剩余9216字)