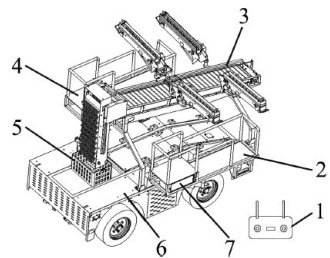

果园作业机辅助采摘装置控制系统设计与试验

打开文本图片集

中图分类号:S24 文献标识码:A 文章编号:2095-5553(2025)07-0091-07

Abstract:Inordertoimprovetheeficiencyfruitpickingandrealizetheintellgentoperationorchardharvest, a controlsystem orchard machine auxiliary pickingdevice basedon STM32 is designed.Thesystem consists a corecontrolleranda wirelesscontroller.Thecorecontrollerreceives the istructions from the wirelesscontrollrtocontrol thehorizontal expansionandcontraction thepickingplatformandtheself-regulating operation the fruit conveyorsystem.Aself-regulating modulefruitconveyorbeltbasedonincrementalPIDcontrolalgorithmisdesigned, which canautomaticallyadjustthe linearvelocity conveyorbeltaccording tothenumber fruits.Thena temperatureself-regulating modulecorecontrolerisdesignedWhenthetemperaturethecorecontroleris too high, thetemperatureself-regulating moduleisabletoadjust the temperaturethecorecontroler toareliable working temperature.Awirelesscommunicationmoduleis designed,which cansendcontrol instructions operators to the corecontroler torealizethecontrol the picking stationandthefruit conveyor system.Thetest results indicate that thecontrolsystemorchard machineauxiliarypicking devicecanrealize theadaptive speedregulationthefruitonveyor belt,the self-adjustmentthe controler temperature,and the expansionand contraction the picking platform.And the data loss rate is less than 10% when the communication distance wireless controller is within 16O meters.

Keywords:orchard operation machine;auxiliary picking device;wireless control;conveyor belt speed regulation

0 引言

果园采摘作业是水果生产过程中最耗时、最费力的环节,现阶段果园采摘仍以人工为主,机械化程度低,劳动强度大、效率低,严重制约果业经济的发展。(剩余9408字)