数控卧式铣镗床高速主轴松拉刀机构优化设计与应用

打开文本图片集

摘 要:方滑枕类数控卧式铣镗床因其行程较大,主轴尺寸较长,拉刀机构安装在主轴内部,在松刀及主轴旋转时,拉刀机构会产生较大的变形量,对主轴产生较大的振动。通过静力学分析及振动学理论将现有拉刀机构进行优化,经实际工程应用证明:优化后的拉刀机构主轴整体性能明显改善。

关键词:数控卧式铣镗床;拉刀机构;有限元分析;振动;优化

中图分类号:TG531 文献标志码:B 文章编号:1671-5276(2024)02-0092-04

Improved Design and Application of High Speed Spindle BroachMechanism for Horizontal Milling and Boring Machines

JIANG Ang, LIN Yang, CHI Haonan

(Genertec Shenyang Machine Tool Co., Ltd., Shenyang 110142,China)

Abstract:Due to long travel and large-sized spindle of horizontal milling and boring machines, and its automatic broach mechanism installed in the spindle, the automatic broach mechanism will cause deformation amount in spindle rotating or processing, resulting in vibration to spindle. With statics analysis and vibration theory, automatic broach mechanism is optimized. Practical application verifies the remarkable improvement in the overall performance of the optimized automatic broach mechanism spindle.

Keywords:horizontal milling and boring machines;automatic broach mechanism;finite element analysis;vibration;optimization

0 引言

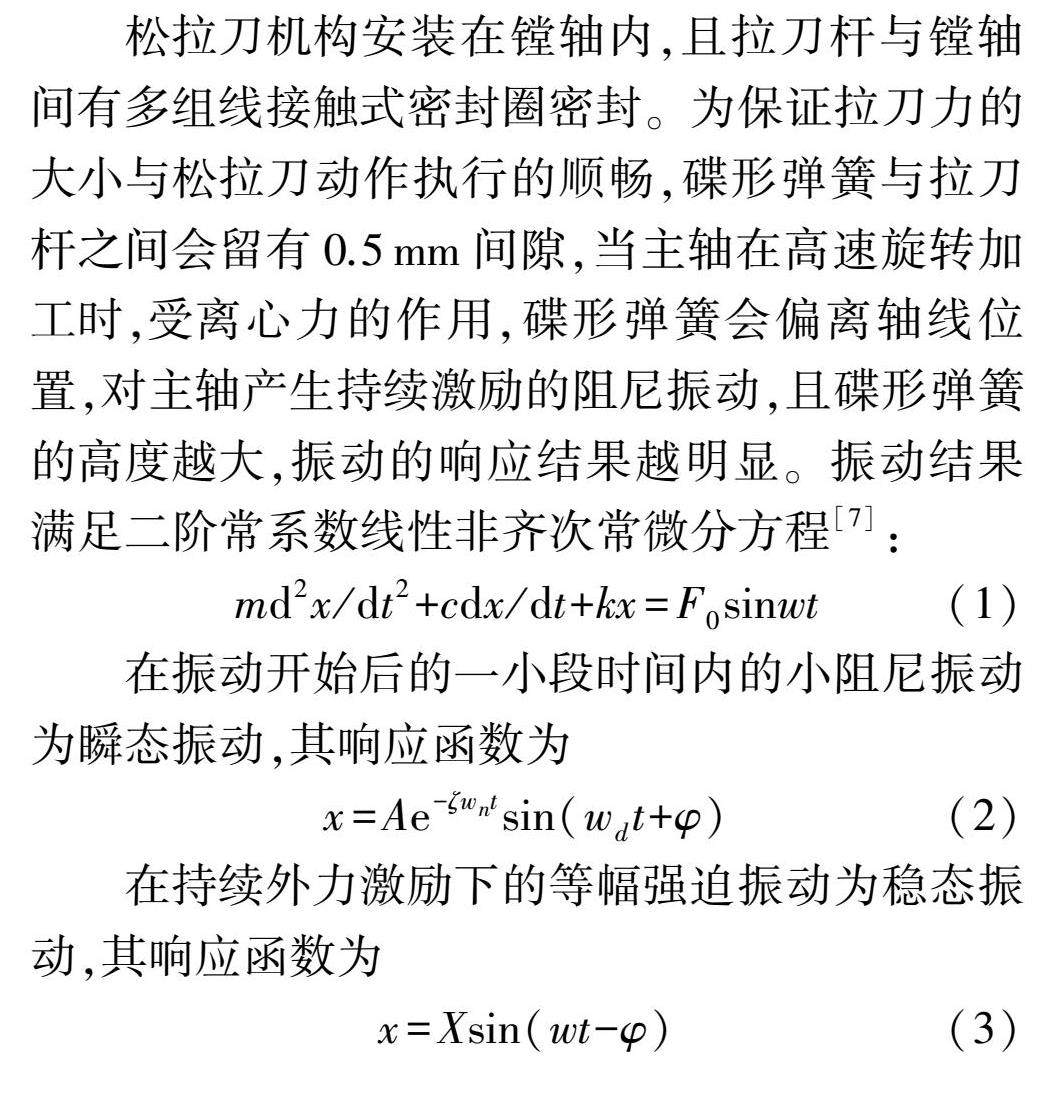

随着机床主轴高速化发展,主轴组件作为高速主轴的关键部件,其高速旋转时的刚性、振动、可靠性对机床精度及寿命至关重要。(剩余4269字)