电解铝车间巡检机器人内部防磁罩设计

打开文本图片集

中图分类号:TP242 文献标志码:A 文章编号:2095-2945(2025)23-0120-04

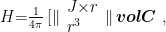

Abstract:Themainstreamprocessintheelectrolyticaluminumindustryistousecryolite-aluminamoltensaltelectrolysisto producealuminum.Thisprocessuseshigh-intensityDCelectricity,resultinginastrongmagneticfieldattheelectrolytic aluminumproductionsite.Withthecontinuousadvancementofelectrolysistechnologythecurentintensityoftheelectrolyticcell series has been upgraded from 300kA and 400kA to 600kA ,which further enhances the on-site magnetic field. In the harsh environmentofhightemperatureandhighdustintheelectrolyticaluminumworkshop,theintroductionofautomatedequipment suchasinspectionrobotshasbecomeatrendHowever,theseequipmentisdiffculttoworkstablyinhigh-intensitymagetic fields,soresearchonmagneticfieldprotectionisparticularlyimportantCurentresearchmainlyfocusesonthemagneticfield distributionofelectrolyticcell,wilethereislitleresearchonmagneticfeldprotectioninelectrolyticaluminumworkshops, resultinginalackofbasisforanti-magneticdesignofautomatedequipment.Thisstudyconducteddesignresearchonthe antimagneticstructureforthespecificenvironmentofthelectrolyticaluminumworkshop,includingtheevaluationofthemagnetic shieldingperformanceofantimagneticcoverswithdiferentmaterialswallthickneses,crosssectionsizeandnstingschees,in orderto provide effective guidance for antimagnetic automation equipment.

Keywords: electrolytic aluminum; inspection robot; magnetic field; anti-magnetic cover; automation equipment

当前,在电解铝行业中,主流的工业制铝方式是通过冰晶石-氧化铝熔盐电解制铝。(剩余3611字)