模具冷却系统优化及其对成型质量的影响

打开文本图片集

中图分类号:TQ320.52 文献标志码:A 文章编号:2095-2945(2025)23-0058-04

Abstract:Aimingattheimpactofmoldcoolingsystemonproductqualityduring injectionmolding,systematicoptimization researchwascariedoutoncoling channeldesign,cooling mediumselectionandtemperaturecontrolsystem.Amethod combiningnumericalsimulationandexperimentalverificationwasusedtocompareandanalyzethecolingefectsbeforeand afteroptimization.Researchshowsthattheoptimizedcolingsystemreducesthemaximum temperaturediferenceonthemold surface from 15qC to 5‰ ,and shortens the product cooling time from 15 seconds to 12 seconds.Product quality has ben comprehensively improved,with key size deviations reduced by 65 % ,surface roughness reduced from 1.6 μm to 0.8μm ,and internal stress reduced by 30.6% . Theeconomic benefits are significant, with the production cycle shortened by 20% ,the defective rate reduced by 75% ,and energy consumption reduced by 23.5% . The research results provide important reference for the design and optimization of mold cooling systems.

Keywords:moldcolingsystem;coolingchanneldesign;temperaturefielddistribution;formingquality;processoptimization

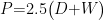

模具冷却系统是注塑成型过程中的关键环节,其性能直接影响产品质量和生产效率。(剩余8243字)