高速动车组联轴节轮齿异常磨耗研究

打开文本图片集

中图分类号:U270.33 文献标志码:B doi:10.20213/j.cnki.tdcl.2025.03.018

Abstract:Based on the abnormal wear fault of the coupling gear teeth of high-speed EMU,the mechanism of suficient lubrification of the couplings of high-speed EMU and the matching relationship between the gear teeth and the contact hardness have been analyzed and studied,a method for calculating the grease injection amount of coupling has been proposed,meanwhile,the grease injection amount of the grease lubricated coupling has been recalculated to obtain the theoretical grease injection amount of coupling. According to the calculation result,this grease injection amount of coupling is relatively less. In addition,as some grease leaks during transportation and asembly,the actual grease weight further decreases compared to the initial state during truck loading. Through macroscopic morphology inspection,microscopic morphology inspection and metallographic analysis of the drum gear and the annular gear of coupling,it turns out that the severe wear of the annular gear root is caused by insuficient nitriding depth of the annular gear and a large difference in surface hardness between the drum gear and the annular gear. When the annular gear root is repeatedly chip worn,the surface hardness further decreases,aggravating the wear of the annular gear root. This conclusion gives a guidance for the design of the grease injection amount and the gear tooth surface hardnessof the grease lubricated coupling of high-speed EMU and has certain guiding significance for engineering applications.

Key words: coupling; high-speed EMU; grease injection amount; surface hardness; gear teeth

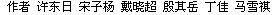

联轴节是高速动车组传动系统中至关重要的机械部件,其作用是连接牵引电机和齿轮箱进而实现两者之间扭矩的传递,除此之外联轴节通过自身变位对两者轴向和径向产生的相对位移起到自动补偿作用,在保障高速动车组安全运行的同时也提高了动车组的运行品质。(剩余4731字)