微型绿色智能制造循环生态体系探索与应用

打开文本图片集

中图分类号:TG335 文献标志码:B doi:10.20213/j. cnki. tdcl. 2025.03.008

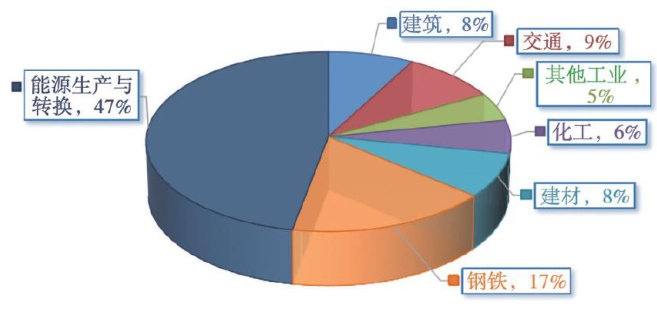

Abstract:The article analyzes the development of intelligent manufacturing systems and the composition of thecarbon emission field in China,determines thepathof accelerating the integration of green intellgent manufacturing and proposes the construction and application of the circular ecosystem of micro green inteligent manufacturing. Through the exploration of the industrial circular ecosystem,the tank pickling operation process has been selected to build a model and under the guidance of the zero-emision path,and the composition of subsystems under the circular ecosystem of micro green inteligent manufacturing has been determined. Then it demonstrates the internal influence factors from different aspects such as intellient operation pattern,resource recycling and green environment maintenance.Based on the actual operation of the waste heat recovery and circulation system,the inteligent pickling operation system and the waste water treatment and circulation system,effective ways of process innovation,cost reduction and eficiency increase are extracted so as to prove the scientific and advanced operation of the system. Through one year of exploration and application of the circular ecosystem of micro green intellgent manufacturing,the anticipated effects are evaluated and the problems are found so as to progressvely improve the system architecture,extend the system functions,laying a solid foundation for subsequent innovation of the green manufacturing process and the R&.D of intelligent manufacturing equipment during the life cycle of the product.

Key words: circular ecosystem of micro green inteligent manufacturing;industrial circular ecosystem; waste heat recovery and circulation system;intelligent pickling operation system;waste water treatment and circulation system

《中国制造2025》明确了5项重大工程及十大重点领域,其中交通装备制造业要实现智能、绿色发展,就需要经济效益和社会效益的协调优化,配合车箱一体化技术优势,推进集装箱制造多元支撑产业的绿色化、智能化发展进程,其微型绿色智能制造循环生态体系在罐箱制造过程中的探索与应用显得尤为关键与重要[1-2]

1绿色智能制造现状及发展情况

1.1 国内智能制造系统发展情况

2015年以来,中国智能制造工程实施工作逐步开展,顶层规划、试点示范、标准体系建设有效推进,全社会发展智能制造的氛围逐步形成。(剩余6212字)