多次焊接对不锈钢焊接接头组织和力学性能的影响

打开文本图片集

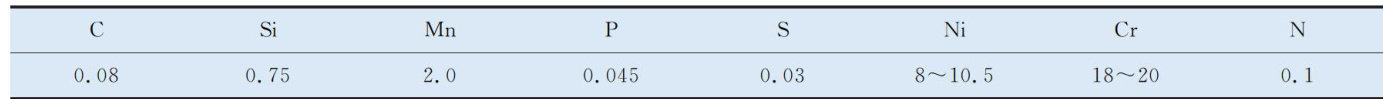

关键词:多次焊接; 06Cr19Ni10 ;晶间腐蚀;力学性能;金相组织中图分类号: U270.4+1 文献标志码:B doi:10.20213/j.cnki. tdcl.2025.03.009

Abstract:The article studies a O6Crl9NilO stainless steel plate thick of 4mm and the impact of three welding cycles and rapid cooling after welding (water spraying) on the properties of the welded joint on it and analyses the influence of multiple welding cycles and rapid cooling after welding on the metalographic structure and the mechanical properties of the welded joint through the metallgraphic structure and the tensile test.The results of the metalographic structure test show that after heat accumulation by multiple welding cycles,the metallgraphic structure of the heat affected zone of the joint changes significantly,gradually transforming from uniform and fine grains to coarse and irregular grains;Through rapid cooling treatment after welding,the heat application time is significantly shortened.Due to the coarse and irregular grains in the heat afected zone at the weld seam,the grain size changes litle. The results of the mechanical performance test indicate that the fracture location of the tensile sample is at the weld seam. As the number of welding cycles increases,the average tensile strength of the sample decreases to varying degrees. The energy spectrum analysis shows that the Cr content in the heat affected zone slightly decreases and there is no obvious intergranular corrosion. The test results providea theoretical basis for evaluating the impact of heat affected zone overlapping caused by multiple welding cycles on the metallographic structure and the mechanical properties.

Key words: multiple welding cycles; 06Cr19Ni10 ; intergranular corrosion; mechanical properties;metallographic structure

不锈钢是不锈耐酸钢的简称,因其防腐蚀性强、持久耐用性能好,自问世以来广受人们的青睐[1],被广泛应用于航空、航天以及汽车等领域[2。(剩余6380字)