新型30t轴重重载车车体关键技术研究

打开文本图片集

中图分类号:U272 文献标志码:B doi:10. 20213/j.cnki. tdcl.2025.03.014

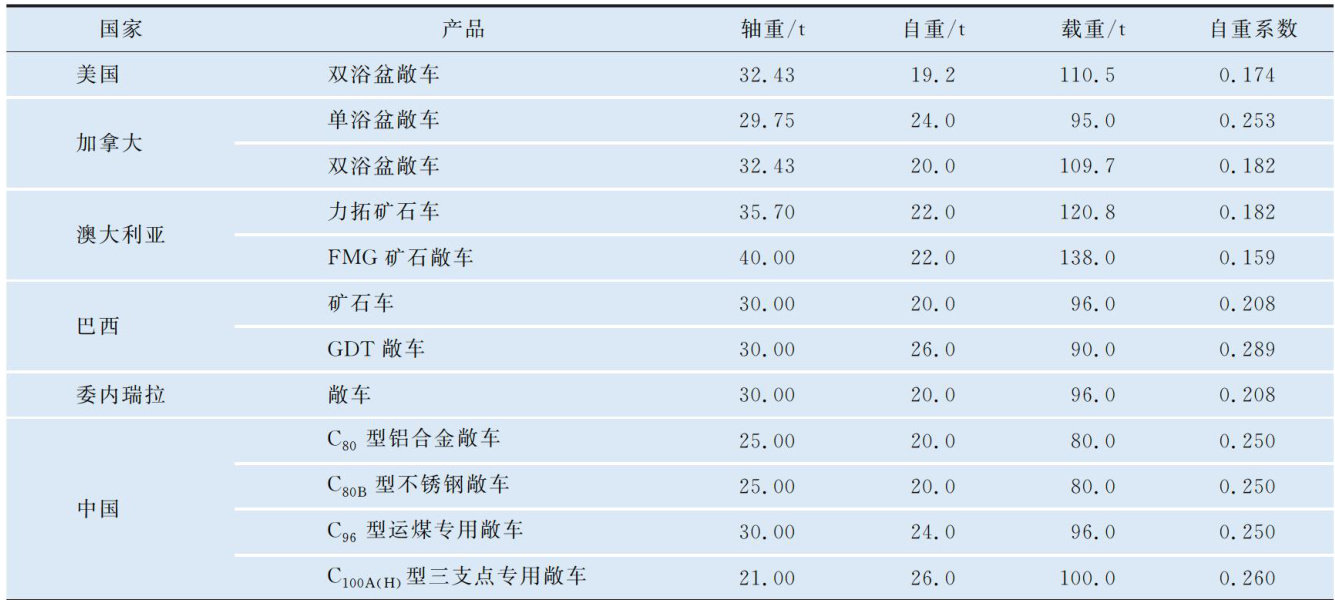

Abstract: The development trend of railway heavy haul freight cars is reducing the dead load and increasing thecarrying capacity,therefore,thecarbody light-weight design is an important link to achieve the reduction of dead load of heavy haul freight cars.The article introduces the key technology for light-weight carbody of the new 30t heavy haul gondola car to optimize the design of the carbody structure of gondola car and describes the finite elementanalysis and thecalculationoffatigue lifeof the carbody in the new structure.The results show thatthe key technology for light-weight carbody of the new heavy haul gondola car can efectively reduce the dead load of the car and increase its carying capacity;that the new carbody is better adapted to the infrastructure;that the optimized structure and the highly corrosion resistant steel allows to realize the maintenance-free lifecycle of thecarbody;and that the dead load coeficient is about O.2,and compared to the carbody of C96 gondola car,the dead load of the new carbody is reduced by 2t and its carrying capacity increased by 2t . The static strength and the stiffness of the new carbody has been verified in accordance with the standard TB/T 3550.2—2019,and the result of static strength calculation indicates that the maximum Von Mises stress doesn’t exceed the permisible stress of the material under four working conditions and can meet the requirement of strength design;that the deflection span ratios of the lower beam and the middle beam of the new carbody are 0.185/2 000 and 0.644/1 500 respectively,both of which meet the stiffness design requirements;and that according to the load spectrum in the AAR M standard,the fatigue lifeof weld seams of the verified new carbody meets the requirement of a 25-year service life.

Key words: heavy haul freight car;carbody of gondola car; light-weight; strength analysis;fatigue life

铁路是国家重要的基础设施,是国民经济的大动脉,铁路建设在国家综合交通体系建设中处于重要地位[1]。(剩余9258字)