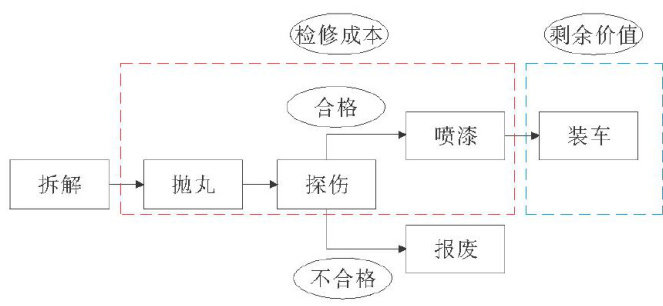

重载铁路货车钩舌检修经济性研究

打开文本图片集

中图分类号:U272 文献标志码:B doi:10.20213/j.cnki.tdcl.2025.01.029

Abstract:The increase in the load,composition and train turnover rate of CHN Energy railway freight cars has resulted in an increase in the longitudinal force of the train and a rise in the frequency of action,thereby deteriorating the operating conditions of the coupler and coupler knuckle and significantly reducing the fatigue lifecapability.Fatigue cracks have become the main failureform of coupler knuckles.In order to make full use of the service life of the coupler knuckle and reduce the maintenance cost,this paper counts,based on the maintenance data of 16H coupler knuckles for heavy-haul railway freight cars of CHN Energy, the scrap rate of coupler knuckles due to fatigue failure at various service times. It proposes a reasonable scrap period for coupler knuckles from the perspective of maintenance cost and residual value,and suggests optimizing the existing maintenance mode according to the reasonable scrap period. This would provide data support for rational use of the service life of coupler knuckles,the reduction of maintenance costs,and improvement of maintenance procedures.

Key words: heavy duty railway freight car; coupler knuckle; fatigue; scrap rate;maintenance;economical efficiency

随着国家能源集团铁路货车的载重、编组数量和列车周转率的提高,列车间的纵向作用力不断增大且作用频次不断增加,使得重载货车用16H型钩舌的运用工况日趋恶化[],根据国家能源集团车辆检修单位反馈的故障情况:目前,在以万t和2万t编组为主要运输模式的情况下,16H型钩舌的裂纹失效比例在万吨编组条件下大幅提升,主要裂纹部位为钩舌牵引台;由于磨耗超限而导致钩舌失效的比例极小,钩舌磨耗相对严重的部位为尾部厚度,磨耗速率为 0.19mm/ 年,其余部位磨耗轻微。(剩余3206字)