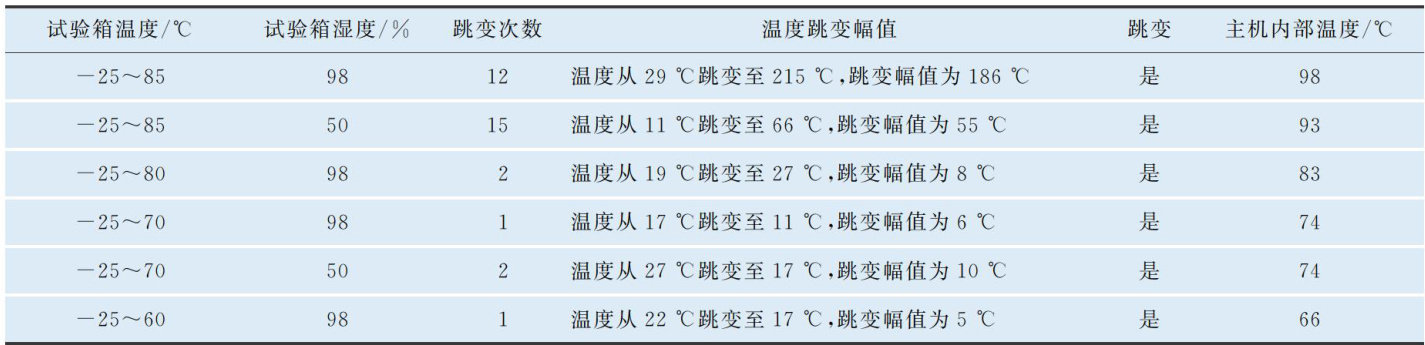

某型动车组轴温检测系统温度跳变问题研究

打开文本图片集

中图分类号:U270.38 文献标志码:B doi:10.20213/j.cnki.tdcl.2025.01.025

Abstract: The EMU axle temperature detection system (referred to as the“BMS system") is a retrofit project combined with advanced repair.Due to the vehicle installation environment,the host of the BMS system is installd in the equipment cabin under the vehicle,and the structural design is compact,the heat dissipation effect is poor,and the component performance is reduced.Plus,the existing alarm logic of the BMS system host is too strict and does not consider the actual temperature change. The superposition of the two is prone to jumping in temperature. Therefore,the abnormal jump filtering algorithm and reset jump mechanism are added from the software to filter out the temperature jump.In view of the fact that the spacing between the Pad pin and the PCBof the constant current sourcechip of the acquisition board is smallduring the operation of the host of the BMS system,there is a problem of contact between the Pad pin and hole,which leads to excessive output current of the acquisition board and causes a temperature jump. The Pad pin and bottom hole of the constant current source chip of the acquisition board were insulated by coating green oil. After optimizing the above software and hardware for a certain type of EMU BMS system, no temperature jump is found in the optimized BMS system,and the optimization effect is good.

Key words: EMU;axle temperature detection; jump in temperature; constant current source chip; high temperature

动车组轴温检测系统在列车运行过程中持续检测车辆走行部轴承的温度状态,一旦温度有超温或者超温趋势,列车会发出预警或报警信号,列车网络控制系统根据温度状态对列车进行限速或者施加制动等措施进行实时控制[1]。(剩余4440字)