变轨距轮对中轴套式花键微动磨损仿真分析

打开文本图片集

关键词:变轨距轮对;轴套式花键;键齿修形;齿顶倒圆;微动磨损中图分类号: U260.331+ .1;TH131.4 文献标志码:B doi:10.20213/j.cnki.tdcl.2025.01.007

Abstract:Regarding the freting wear issue of the axle sleeve type spline in the gauge-changeable wheelset, this paper investigates the impact of deflection angle and offset on the contact and wear of the tooth face of the sleeve spline using the Archard wear model. It also compares and analyzes the presure and wear distribution of profiled and unprofiled spline,and studies the impact of various load cycles on the maximum contact pressure and maximum wear depth of the tooth surface. The calculated results indicate that the maximum wear depth increases with the increase in deflection angle and offset.When there is deflection angle,the wear of spline teeth mainly occurs at both axial ends of tooth surface,and when there is deflection angle and offset,the wear of spline teeth only occurs at one axial end of tooth surface. There is an interaction between contact and wear properties;after 2×105 cycles of load,when the deflection angle is 0.030∘ ,the maximum wear depth of the profiled spline tooth surface is reduced by 79.2% . When the deflection angle is 0.026∘ and the offset is 0.08 mm ,the maximum wear depth of the profiled spline tooth surface is reduced by 65.9% ,which effectively prolongs the service life of the spline.

Key words: gauge-changeable wheelset;axle sleeve type spline; spline modification; gear tip rounding;fretting wear

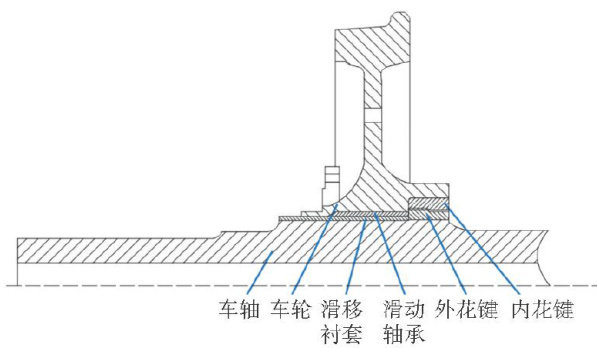

随着“对外开放”和“一带一路”战略的逐步推进,高速变轨距动车组已成为跨国运输的战略性选择,也是解决国际联运难题的最佳方案,相较于传统轮对,变轨距轮对轮轴之间为间隙配合,以此来实现变轨距,即车轮沿车轴的轴向滑移[1-3]。(剩余11674字)