基于三维几何模型的铝合金车体结构自动化建模和仿真

打开文本图片集

中图分类号:U260.32 文献标志码:B doi:10.20213/j.cnki.tdcl.2025.01.012

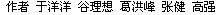

Abstract:Based on the thre-dimensional geometric model of aluminum allycar body,the full-parameter geometric information analysis and automatic finite element mesh generation technology of the aluminum alloy carbody structure are established through self-developed professional software,and the stiffess and modal automatic and rapid simulation analysis of carbody structure are realized.Based on the geometric model of STP format,allthe geometric information needed to establish the finite element model is automatically recognized and captured,and then the crosssection of thecarbodyand various beam and column profiles are analyzed,and their two-dimensional cross-section shape information is automatically extracted. According to the twodimensional shape information of carbody section and beam and column,the center line and thickness are automatically extracted,and their finite element mesh is divided. The plane mesh of the carbody section and the beam and column is stretched along a specific direction,and the nodes are automatically merged according to theconnection between them,soas to generate the three-dimensional finite element mesh of the vehicle structure, andrealize the functions of element attributes and material parameters,element grouping and load condition definition, so as to establish the parametric finite element model of the vehicle structure.By comparing the stifnessand modal of theartificialfiniteelement modelof thecarbody structure,thecorrctness of the parametric finiteelement modelof aluminum alloy carbody structure based on the proposed method is verified.

Key words: aluminum alloy carbody structure;geometric model;automatic mesh generation; stiffness; modal

在铝合金车体结构的方案设计阶段,通过对铝合金车体结构进行有限元分析,校核铝合金车体结构的刚度和强度,不断优化车体断面的形式和梁柱的布局,从而使铝合金车体结构达到更好的力学性能。(剩余12320字)