烧结环冷机组余热回收的数值模拟与应用研究

打开文本图片集

中图分类号: TF802.67 文献标志码:A 文章编号:2095-2945(2025)20-0094-06

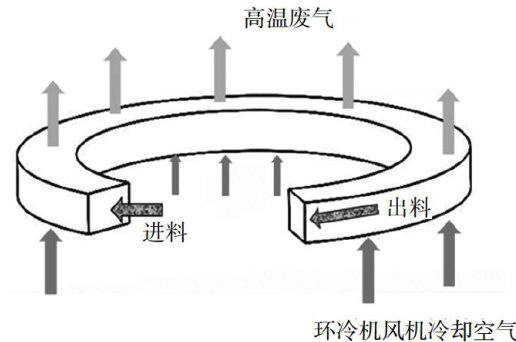

Abstract:ThecircularcolingunitisoneoftheimportantequipmentinthesteelsinteringproductionprocessItisusedto cooltheroastedandrushedhigh-temperaturesinter.Theequipmentventilatedandcoolsheatthroughacircularringsupported onacirculartrackandrotatingaroundafixedcenterofrotation.Inthelong-termproductionpractice,traditionalcircularcoolers haveexposedaseriesof problemssuchasenergywasteandenvironmentalpolutionduetothelimitationsofstructuraland functionalmodels.Basedontheactualproductionmodeofthesinteringringcolingunit,aphysicalmodelwasbuilt,parameter changesattheobservationpointsduringtheentireoperationcycleweresetandrecorded,andtheimpactofvariousfactorson thesinteringcoling efectwasanalyzed.Foursetsofeficientworkingconditionswerescreenedoutwhilemetigthe enterprisesneedsforminerallayercolingwereestablished,andanorganicRankinecyclethermodynamicmodelwasestablished topredictandevaluatethepowergenerationandpowergenerationateachworkingconditionpointandplan.Itisexpectedthat the annual power generation will be increased by 1100×104kWh . Annual standard coal is saved by 3320tce/a ,and annual carbon emission reduction is 9220t-c/a ,which is of guiding significance for actual production.

Keywords:sintered circularcooler;physical modeling;cooling eficiency;fluegas temperature;power generation

钢铁是最重要的工业基础原材料之一,我国年产量达10亿t,占全球产量过半,在建筑、交通等领域扮演着不可或缺的角色。(剩余5091字)