杂粮粉挤压膨化工艺的优化

打开文本图片集

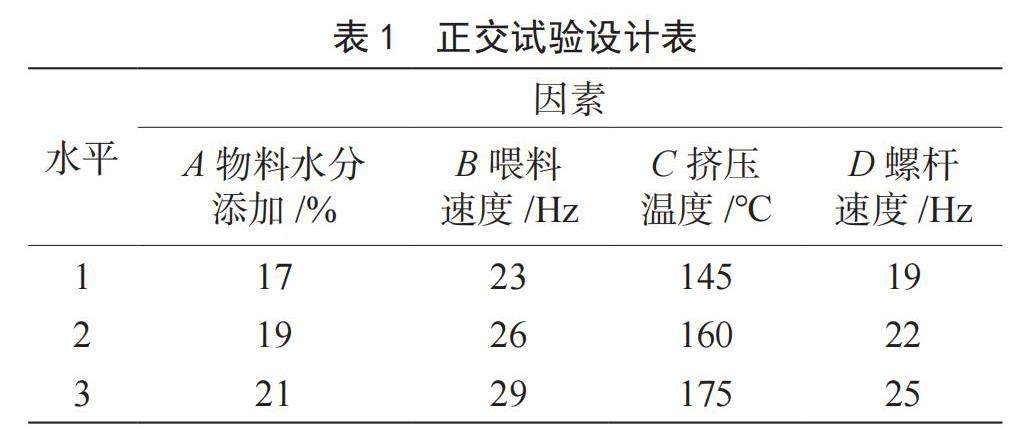

摘 要:以燕麦、薏米、青稞及小米4种杂粮为原料制备了杂粮粉,通过单因素试验和正交试验确定挤压膨化的最佳工艺条件为物料水分添加量19%、喂料速度26 Hz、挤压温度145 ℃、螺杆速度25 Hz,此条件下杂粮粉的糊化度达到89.73%。

关键词:杂粮粉;挤压膨化工艺;糊化度

Optimization of Extrusion Process for Preparation of Coarse Grain Powder

ZHANG Yan, TIAN Haijuan, ZHANG Chuanzhi

(Jilin Business and Technology College, School of Grain Science and Technology, Changchun 130507, China)

Abstract: Four kinds of coarse grains, namely, oats, coix seed, hulless barley and millet, were used as raw materials for the preparation of coarse grain powder, and the optimal process conditions for extrusion and expansion were determined by single-factor and orthogonal experiment to be 19% of the material moisture addition, 26 Hz of the feeding speed, 145 ℃ of the extrusion temperature, and 25 Hz of the screw speed, and the gelatinization degree of the coarse grain powder reached 89.73% under these conditions.

Keywords: coarse grain powder; extrusion process; gelatinization degree

我国杂粮栽种历史悠久、资源丰富、品种多样,素有“杂粮王国”的美称。(剩余2883字)