基于3D视觉技术的动力模组自动跟踪焊接系统研发

打开文本图片集

中图分类号:TP273 文献标志码:A 文章编号:2095-2945(2025)18-0017-06

Abstract:Withthecontinuousdevelopmentofintellgentmanufacturingtechnology,thedeepintegrationofindustrialrobots andmachinevisiontechnologyhasbecomeakeytrendinindustralproduction.Machinevisiontechnologyhasshowbroad applicationpotentialandachievedsignificantresultsinvariousmanufacturingfields.Weldingisacoretechnologyinindustrial production,yettradionalweldingrobotslackadaptiveablityandcanotmeetthehigheficiencyandqualityrequirementsof inteligentmanufacturing:Thisstudy,basedon3Dmachinevisiontechnology,hasdevelopedanautomaticweldseamtracking lasersystemintegratedintoindustrialobots.Thesystemintegrates3Dvisiontechnologydeepleaming,ightingtchnololasr principles,androbotictechnology.Thefocusofthisstudyincludes:First,establishingthemappingrelationshipbetwenimages androbotcordinatesunderthepremiseofcompletehardwareconfiguration;second,performingthecalibrationofthevision system;hen,forulatingthedatatransmissionandeeptionprotocol;nextdisussingimageprocessingtechques;andfinaly usingneuralnetworktechnologytoautomaticallyobtaintheweldseamtrajectory.Throughtestinginactualaplication,thsystem has been verified to meet the actual needs of automatic weld seam tracking welding.

Keywords:image processing;weld seam positioning;3Dvisionsensor;robot welding;lasersensor hand-eyecalibration

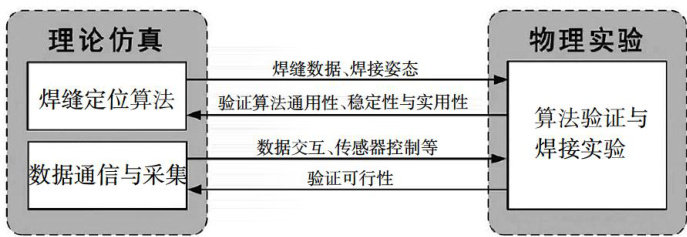

随着电动汽车和储能行业的快速发展,对电池的需求、质量和成本要求越来越高,这推动了激光焊接技术的创新和发展。(剩余6063字)