基于灵敏度分析的中高地板铰接车体整体性能优化设计

打开文本图片集

中图分类号:U270 文献标志码:B doi:10.20213/j.cnki.tdcl.2025.02.013

Abstract:The FEA and the structure optimization technology are used to solve the problem of lower overall performance indices of the middle and high-floor articulated carbody. Firstly,the finite element model for articulated carbody has been built according to the structure carrying characteristics,and it turns out from the analysis that the vertical rigidity of carbodyand the first-order vertical bending vibration frequency of the serviced carbody don’t meet the standard requirements; through displacement and frequency sensitivity analysis,the sensitive main structure profile plate thickness is selected as a design variable of rigidity and frequency optimization. Then the static rigidity and the dynamic frequency are taken separately for objective functions to optimize the dimensions and the thickness of the aluminum profile of the main structure is determined based on the result of optimization.For the optimized carbody under the maximum overload,the maximum vertical displacement of the middle part of side sill of the underframe is reduced to 10.4mm and the first-order vertical bending frequency of the serviced carbody is increased to 10.8Hz

Key words:articulated carbody;serviced carbody module;sensitivity analysis;rigidity optimization; frequency optimization

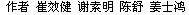

中高地板铰接编组列车具有载客量大的特点,由于其采用铰接转向架连接相邻车体,它的转向架数量比传统车钩连接列车的要少。(剩余5944字)