基于数值模拟的切顶卸压后保护煤柱宽度研究

打开文本图片集

中图分类号:TD322 文献标志码:A 文章编号:1003-5168(2025)13-0049-05

DOI: 10.19968/j.cnki.hnkj.1003-5168.2025.13.009

Study on the Width of the Protective Coal Pillar After Roof Cutting and PressureReliefBased on Numerical Simulation

ZHANGPu1 ZHANG Desheng'LOU Peijie1²HE Haoda'HUANG Puhao1 (1.Anhui University of Science and Technology,Schoolof Civil Architecture,Huainan 232Ooo, China; 2.National Key Laboratory of Coal Fine Explorationand Intelligent Development,China University of Mining and Technology,Xuzhou 221116,China)

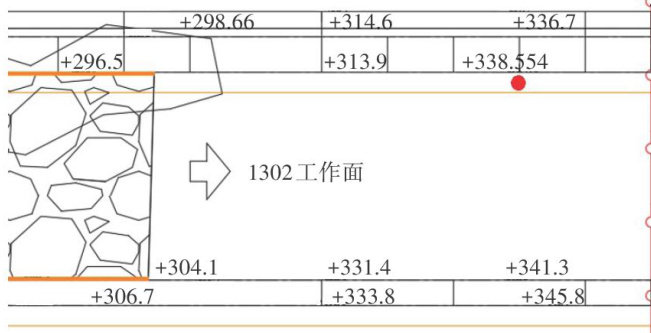

Abstract: [Purposes] In view of the impact of mining disturbance on the west gas drainage roadway of a mine,as wellas that of permanent abutment pressure in the coal pillar after the working face is stopped, the pre-splitting blasting technology for roof cuting and pressure relief is adopted.This notonly protects the roadway and improves recovery rate,but also reduces the width of the protective coal pillar. [Methods] In this paper, FLAC 3D software is used to simulate the stress distribution of roadway surrounding rock underdifferent widths of protective coal pillars after roof cuting and pressure relief,so as to determine the reasonable width of the protective coal pillr.[Findings] The simulation results indicate that with the increase in the width of the protective coal pillar,the degree of vertical stress concentration of the surrounding rock of the roadway decreases.When the width of the protective coal pilla exceeds 50 m, the degree of decrease is no longer obvious. Finaly,a 5O-meter-wide protective coal pillar is selected. [Conclusions] The research results provide a reference for the design of roadways with similar conditions in this area.

Keywords: roof cutting pressure relief; numerical simulation; protective coal pillars; FLAC 30

0 引言

为保证煤炭资源的开采效益,保护煤柱的合理宽度应在保证安全的前提下,做到应采尽采。(剩余3539字)