60Si2Mn弹簧钢加工开裂原因分析

打开文本图片集

中图分类号:TF76 文献标识码:A 文章编号:1008-9500(2025)04-0078-03

DOI:10.3969/j.issn.1008-9500.2025.04.022

Analysis of Cracking Causes in 6oSi2Mn Spring Steel Processing

YANRuopu,CHEN Zhiyue (HBIS Group TangSteel Company,Tangshan ,China)

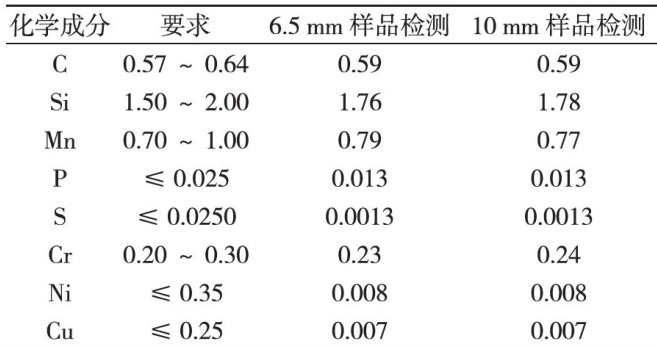

Abstract:The6OSi2Mnhot-rolledcoilpurchasedbyadomesticautomotive parts manufacturing planthas serious cracking problemsduringacidpickling,coldrolling,andcross cutting processesandcannotbeused.Acomprehensiveanalysisof the heating process,rollingproces,factorydecarburizationlayerdata,annealing process,ndpostannealingdecarburiation layerdata of6OSi2Mn springsteel shows thatusing fullhydrogenannealingonhot-rolledrawcoils (withoutacid washing) leads to severedecarburizationand abnormal growthofsurface feritegrainsonthesurfaceof the strip steel.Thesurface decarburizationlayerandabnormally grown feritegrains weakenthe intergranularbonding force,and whenthematerial bendsand deforms,cracks occur along the surface grainboundaries,ultimatelyresulting inquenchingfailureand processing cracking of the steel plate.

Keywords: spring steel; processing cracking; decarburized layer

随着汽车行业的飞速发展,在保证车身强度的前提下,汽车轻量化逐渐成为众多车企的关注点。(剩余1911字)