基于神经网络的模具振动信号故障诊断

打开文本图片集

中图分类号:TG76 文献标志码:A

FaultDiagnosisofMold VibrationSignalsBased on NeuralNetwork

WU Dejun, YANG Wei

(Shaanxi Institute of Technology,Xi'an 71O3oo,Shaanxi,China)

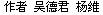

Abstract: Aiming at the common faults in mold operation, this paper puts forward a fault diagnosis method of vibration signal based on neural network. In this study,an experimental platform was built to collect vibration signals in four typical fault states: normal,eccentric, crack and wear,and an end-to-end classification model was built with the help of convolutional neural network (CNN), so as to realize automatic identification of die states. In this study, a multi-layer convolution-pooling structure is designed to extract time-frequency features,and ReLU activation function and Softmax output layer are used to complete nonlinear mapping and classification decision. Experiments show that the accuracy of the proposed model on the test set is 95.6% ,which is obviously better than SVM,KNN and traditional BP neural network (BPNN). When wavelet packet coeficients are used as input features, the model recognition performance is the best,and the accuracy rate is 93.5% . Through confusion matrix analysis,except for a few cracks and wear samples, the other categories are well distinguished. It can be seen that the fault diagnosis model based on CNN has strong generalization ability and potential for engineering application,which provides an intelligent scheme for mold condition monitoring.

Key words: mold fault diagnosis; vibration signal; neural network; feature extraction; convolutional neural network (CNN)

0 引言

模具运行状态对产品质量、生产效率,以及整条产线的稳定性有着直接影响。(剩余10104字)