塑料模具钢718钢板内部质量优化分析

打开文本图片集

中图分类号:TG76 文献标志码:A

Internal quality optimization analysis of 718 plates for plastic Die Steel

OUYANG Yu, YU Hao, BAI Xuefei,MA Xin, ZHEN Xingang(Rizhao Steel Yingkou Medium Plate Co. Ltd.,Yingkou,1150O5 Liaoning,China;Liaoning Medium Plate Professional Technology Innovation Center,Yingkou ,Liaoning,China)

Abstract: In order to solve the problem of uneven cross section of plastic die steel 718 rolled by continuous casting slab,the methods of cold acid etching,metallography,macrohardness and microhardness were used to analyze the results. The results show that the composition segregation leads to the formation of martensite in the core of the steel plate,and the core martensite cannot be completely transformed by a single tempering under the condition of bad furnace. The untransformed martensite is the main reason for the uneven sawing section. By optimizing the light pressing process to improve the segregation of the components of the billet,By controlling the burner failure rate and secondary tempering treatment, the martensitic transformation can be promoted,and the problem of uneven sawing cross-section can be solved.

Key words: uneven cross section; segregation of composition; anomaly microstructure;martensitemicrostructure

0 引言

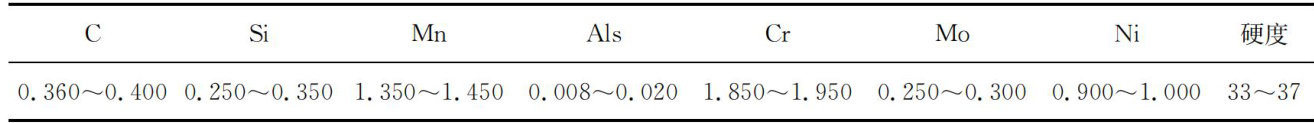

718模具钢是瑞典的模具钢牌号,相当于我国的 3Cr2MnNiMo ,是通用型镜面塑料模具钢,由于传统的P20模具钢只能保证厚度不大于350mm 模块的淬透性,通过添加镍元素来提高淬透性,可以弥补P20模具钢在大截面模具淬透性方面的不足,使其具有较高的淬透性而被广泛用于大型、精密、复杂及镜面抛光的塑料模具,并且具有淬火不变形开裂,精度高,制模周期短等优点,已成为大型高端塑料模具的首选[1-5]。(剩余6957字)