保压压力对低压铸造AISi7Cu合金组织和力学性能的影响

打开文本图片集

中图分类号:TG441.8 文献标志码:A

Effect of holding pressure on the microstructure and mechanical properties of low-pressure casting AlSi7Cu alloys

XU Tong, LI Yong, WANG Chao, XUE Xudong (Shaanxi Railway Insttitute,Weinan714Ooo,Shaanxi, China)

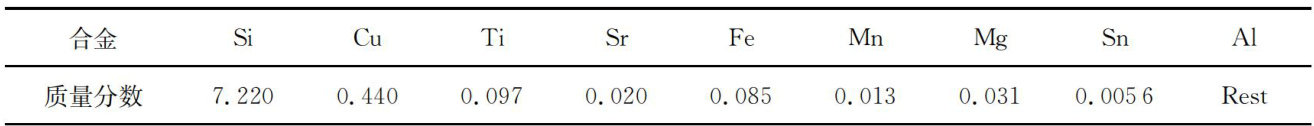

Abstract: In this study, the specific effects of these changes on the microstructure of AlSi7Cu alloys and their mechanical properties were investigated by adjusting different levels of holding pressure during the low-pressure casting process. It was found that the fabricated AlSi7Cu alloy samples exhibited a more compact microstructure and more rounded eutectic Si particles under higher holding pressure conditions. In addition, the filling properties of the alloys were enhanced and the porosity defects were significantly reduced under this condition,which led to a significant improvement in the mechanical properties of the alloys. Specifically,a gradual decrease in grain size and a corresponding increase in grain refinement were observed at three different holding pressure levels of 75,150, 225kPa . Specific data showed that the grain size and secondary dendrite arm spacing of the alloys reached 231,182, 134μm and 43.4,35.9, 28.6μm ,respectively. Meanwhile, the density and porosity at the three holding pressure levels were recorded to be 2.638,2.651, 2.670g/cm3 ,and 0.973% , 0.807% ,and 0.406% , respectively. In terms of mechanical properties,the tensile strength,yield strength and elongation of the AlSi7Cu alloy were reported as 247.67MPa , 195.68MPa , 4.13% ;261.54 MPa, 198.80MPa , 5.07% ; 265.38MPa ! 199.31MPa , 7.44% ,respectively, showing 7.15% , 1.86% and 80.1% increases. All these data indicate that increasing the holding pressure can effectively improve the microstructure and mechanical properties of the alloy.

Key words: AlSi7Cu; microstructure; mechanical properties; low-pressure casting; pressure

0 引言

AlSi7Cu铸造铝合金作为近共晶铸造铝合金的一个重要代表,因其优异的铸造性和机械性能而被广泛应用于航天、航空及机械工程领域[1-2]。(剩余7050字)