国外某铜冶炼厂烟气收尘系统的改造分析

打开文本图片集

中图分类号:TF811;X758 文献标志码:B 文章编号:1004-4345(2025)05-0024-04

Abstract To meettheofgashandlingdemandsafterproductionexpansion,ananalysisoftheprocessflowandoperationalstatus was conducted to address issues in the existing offgas & dust handling system of an overseas copper smelter,such as excessive equipmentoperatingload,ashaccumulationinpipelines,andhighenergyconsumption.Whilemaintainingtheoreproces flowof “Ausmelt smelting + Rotary holding Furnace +PS Converter converting + Rotary Anode Furnace refining” unchanged, some specific renovationmeasureswereproposed,uchasmplementingforediculatiointeAusmeltfuacewasteatboilerxpdgte electric fieldsoftheelectrostaticprecipitator,eplacingthespraycolerwithawasteheatboiler,andoptimizingtheanodefurace dusthandlingprocess.Afterenovationthesyste'sprocesingcapacityandoperationaleficiencywereehancedfectively achieving wasteheatrecoveryandcomprehensiveresourceutilization,whilesignificantlyreducingoperatingcostsandenvironmental risks.

Keywords copper smelter;offgas &dust handling; technical renovation; waste heat recovery;systemoptimization

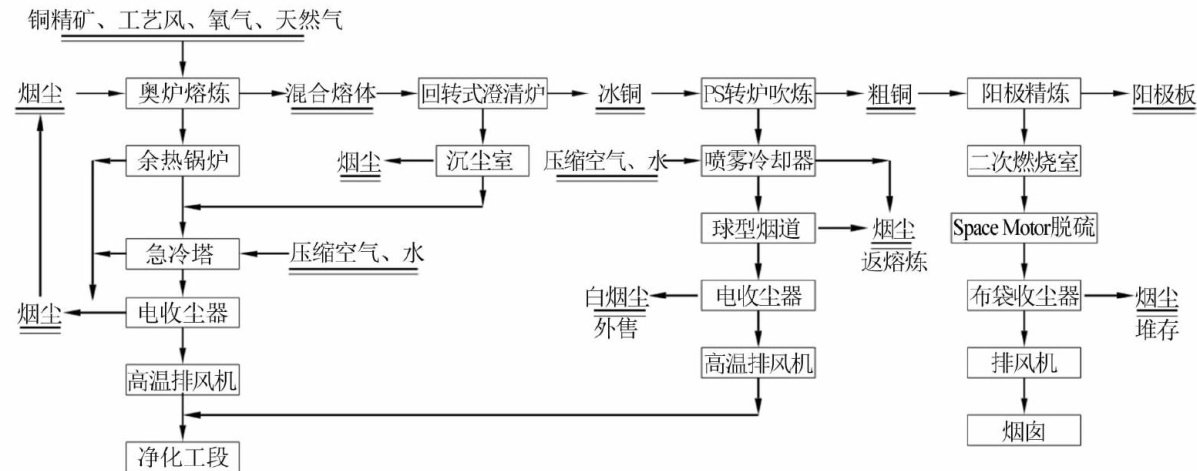

国外某冶炼厂建厂初期采用的是鼓风炉熔炼工艺,后为提高冶炼厂自动化水平与规模效益,降低生产成本,改善操作条件,该厂引进Ausmelt工艺,并于2007年投产并运行至今,规模约18万 Δt/a ,其主工艺流程为“Ausmelt熔炼 + 回转式澄清炉 +PS 转炉吹炼 + 回转式阳极炉精炼”。(剩余4999字)