高可靠全方位智能螺纹紧固装配管控系统

打开文本图片集

High-reliability and Al-around Intelligent Thread Fastening Assembly Control System

PANLihui,XUJunsheng,ZHANGQihe (Shandong CRRC Tonglida Intelligent Equipment Co.,Ltd.,Jinan 25oo22,China)

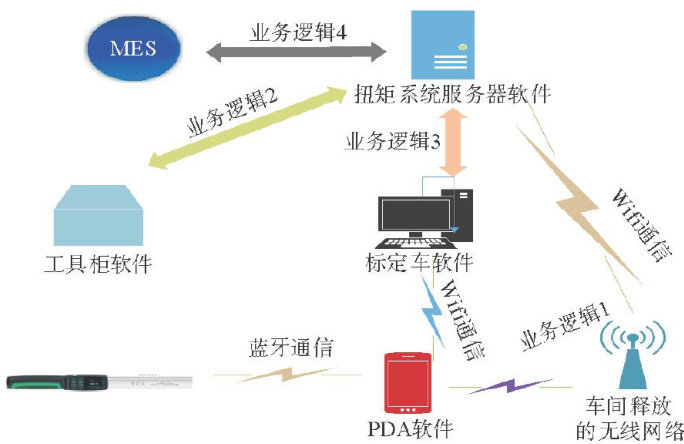

Abstract:Nowadays,Chinese manufacturing industry is flourishing.Although the deep application of intellgence and information technologies in many fields has promoted significant improvements of production efficiency and product quality,manual tightening methods are stillused in a large part of the manufacturing industry.Although some companies have established the assembly tightening systems,most of these systems can only simplycollect and record relevant tightening data,which is dificult to meet the high standard requirements of modern production for fullprocess quality control and can’t comply with the requirement of quality management for a comprehensive control of the whole process including human,machines,material, method and environment. Therefore,considering the overal reality of some weak manufacturing sectors at present,anall-aroundand high-reliability intellgentthread fastening assembly control system hasbeen designed.It can really take the five production elements of human,machine,material,method and environment as the core starting points in limitedconditions,cover all the key steps that may affect the tightening quality in production and solve a series of problems such as how to judge whether the personnel's working state is good,whether the tool is used in a balanced way,how to inspect the state of tightening tools, whether the production is well operated and how to shield the impact of the noisy environment on site on the returnof tightening data,thereby achieving theeficient andreliablequality controlin limited resources and conditions.

Key words: quality management theory;industrial internet; intelligent assembly; thread fastening; tightening solution

据国家统计局公布的数据,我国共有384万余家 制造业企业,其中中型规模以上制造业企业的数量为37.3万,占比仅为 9.7% ,因此我国制造业整体呈现出“数量多、规模不大"的现状[1]。(剩余4898字)