低碳氢基熔融还原炼铁技术探讨

打开文本图片集

中图分类号:TF557 文献标识码:B 文章编号:1003-0514(2025)04-0014-07

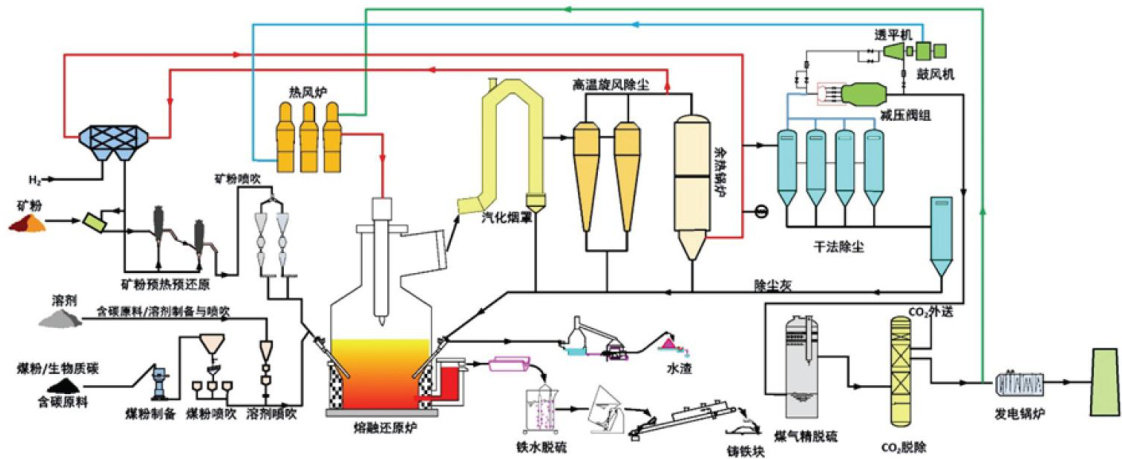

Abstract:Thenewprocessof hydrogen-carbon-basedmoltenreductionironmaking (two-step method)centersonamolten reductionfurnace.thefront-end procedure employs ahydrogen pre-reduction processforionorepowder(such as fluidized bed),where the producedhigh-carbonhotmoltenironcanbedirectlysuppliedasqualifiedhigh-purityironmetalproducts afterdesulfurization.Theby-productmoltenreductionfurnacegasundergoesdechlorinationanddesulfurizationtoeiciently recover sulfur in elemental form, meeting ultra-low emission requirements of SO 2⩽ 35 mg/Nm³ after combustion. The hightemperature,high-pressure gas generatedbythe molten reduction furnace issequentiall recovered through vaporization hoods,settlingchambers,cyclone dustcolectors,and wasteheatbilers.Thisprocessconvertsitintomediumtemperature, high-pressure gasforbaghousedrydustremoval.Theresidualpresure energyfrom the molten reduction furnacegas is then transferred tothe BPRT(orTRT)turbineunit,converting itspressureand thermal energyinto power forbloweroperation to achieve energy conservation and emission reduction goals.Through comprehensive comparative analysis of process energy consumption,carbon emissions,and polltant emissions between the new hydrogen-carbon-based molten reduction ironmaking processandtraditionallong-processironmaking procedures,thetechnical innovationand feasibilityof thenew hydrogen-carbon-based molten reduction ironmaking process have been further verified.

Keywords:moltenreductionfurnace;ironore powder hydrogenpre-reduction;stepwise waste heat recovery;residual pressure energy recovery;energy-saving and emission-reduction

1概述

炼铁行业面临着在资源、能源、环保和碳排放方面前所未有的压力,传统高炉炼铁工艺的炼铁流程长,需要焦化厂、烧结厂、球团厂3个厂来支持,投资高、占地面积大、污染严重、碳排放量大、成本高。(剩余5351字)