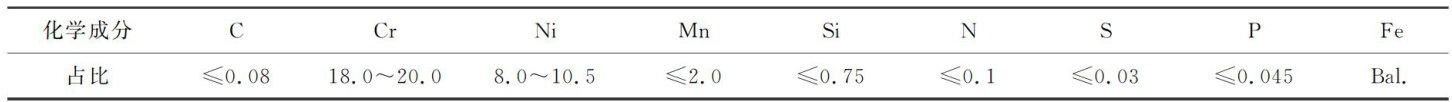

304奥氏体不锈钢A-TIG焊接头组织与力学性能研究

打开文本图片集

中图分类号:UG405 文献标志码:B doi:10.20214/j.cnki.zhgdjt.2025.06.013

Abstract:This study employed an activated flux composition of 63%SiO2+6%MnO2+16%Cr2O3+ 15% (204 Al2O3 for A-TIG welding of 304 austenitic stainless steel. The microstructure and mechanical properties of weld joints were systematically characterized through macroscopic metallography,scanning electron microscopy(SEM), energy-dispersive X-ray spectroscopy(EDS), tensile testing,and hardness measurements. The results demonstrate that compared to conventional TIG welding,A-TIG welding achieves complete joint penetrationand produces defect-free stainless steel weld joints. The fusion zone primarily consists of distinct columnar dendritic crystals growing perpendicular to the fusion boundary. EDS area and line-scan analyses reveal homogeneous elementaldistribution across both the fusion zone and heat-afected zone (HAZ),with no significant chemical transition regions observed,indicating absence of elemental segregation at the fusion line/HAZ interface.Furthermore,the tensile properties of A-TIG welded joints closely match those of the base metal,exhibiting an optimal strength-toughness balance,which confirmsexcellent mechanical performance of the joints. This study establishes a foundation for optimizing A-TIG welding processes and tailoring microstructure-mechanical property relationships in A-TIG welded joints.

Key words:304 austenitic stainless steel;A-TIG;weld joint;microstructure;mechanical properties

不锈钢因具有耐腐蚀性强、强度高及塑性好等优点,被广泛应用于轨道交通、航空航天及核电装备等领域[1-3]。(剩余5713字)