高速车体关键尺寸自动测量系统的研究与应用

打开文本图片集

中图分类号:U270.32 文献标志码:B doi:10.20214/j.cnki.zhgdjt.2025.06.010

Study and Application of Automatic Measurement System for Key Dimensions of High-speed Train Bodies

LIU Jingbo,MA Biao,PAN Xiaohu,KOU Xu, SONG Yan,WEI Qingsong (CRRC Tangshan Locomotive&Rolling Stock Co.,Ltd.,Tangshan O63035,China)

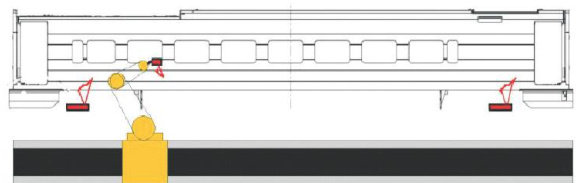

Abstract:To address thechallenges of high measurement difficultyand low accuracy in manual inspection ofcritical dimensions for finished high-speedcar bodies,this system integrates vision sensors,industrial robots, motion rails,and an upper computer. Structured-light cameras scan and capture images of key feature points on thecar body surface.These images are compared with pre-defined templates to identify features such as surfaces,edges,and holes. The system employs Zhang’s calibration method for camera calibration and establishes an optical plane equation. The pixel coordinates of feature points undergo a series of coordinate transformations,from the pixel coordinate system to the image coordinate system,camera coordinate system, robot flange coordinate system,robot base coordinate system,and rail coordinate system,before being converted to the body coordinate system.Based on the relationship between measurement points and target dimensions,a dimensional algorithm model is developed to ensure high-precision automated measurement.Use RobotStudio programming software to optimize robotic measurement trajectories and generate code for position fine-tuning.Upon the completion of car body,therobot program is called to automatically measure the dimensions.The calculated dimension measurement values are compared with the nominal values to determine the dimension deviation range and calculate the dimension deviation trend. Compared with the manual Leica measurement data,it was found that the minimum error of the automatic measurement system was O and the maximum error was 0.22% . The relative error of the automatic measurement system was lower than that of the manual Leica measurement results.The system has the characteristics of high degree of automation,fast measurement speed,short production cycle and low recognition error rate.

Key words:vision sensor;industrial robot;motion rail;measuring dimension;algorithmic model

随着国内机器人技术的不断发展和视觉检测技术的大量应用,基于高速车体在制造过程中关键尺寸的检测需求,搭建了高速车体自动化测量系统,采用工业机器人及运动导轨为柔性运动平台,结合激光视觉检测技术及工业机器人高精度运动控制技术,实现了高速车体关键尺寸自动测量,并监控尺寸波动趋势。(剩余11906字)