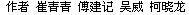

基于半刚性气囊的反应烧结碳化硅精密抛光特性

打开文本图片集

中图分类号:TG580.62 文献标志码:A

Precision Polishing Characteristics of Reaction-bonded Silicon Carbide Based on Semi-rigid Bonnet

CUI Qing-qing1,FU Jian-ji²,WU Wei³,KE Xiao-long' (1. School of Mechanical and Automotive Engineering,Xiamen University of Technology, Xiamen 36l024,China; 2. Sabin Dong Institute of Micromaterials and Nanotechnology, Xiamen University,Xiamen 36llO2,China;3. State Key Laboratory of Ultra-precision Machining Technology,Hong Kong Polytechnic University,Hong Kong 999077,China)

Abstract:The experiment was conducted to analysis the performance of a semi-rigid bonnet in the precision polishing of reaction-bonded silicon carbide,aiming to investigate its material removal characteristics and surface quality improvement effects. The 3D morphology of the polished surface was obtained using a white light interferometer,and the spherical characteristics were verified through 2D cross-sectional profiles to evaluate the high-precision polishing outcome. The results show that the amount of material removed increases progressively with longer dwell time and higher spindle speed. After polishing with the semi-rigid bonnet,the surface roughness of the workpiece decreased from 251.69 nm to 8.72nm ,with a reduction of 96.54% ,which significantly improved surface uniformity and reduced microscopic defects.

Keywords: material removal; bonnet polishing;precision polishing;semi-rigid bonnet

精密抛光是一种高效的加工方式,用于提升材料表面质量,尤其在高硬度材料和精密器件的制造中。(剩余7839字)