基于废FCC催化剂的陶瓷/碳复合材料的制备及其吸波性能

打开文本图片集

文章编号:1003-9015(2025)02-0352-13

中图分类号:TQ174.7 文献标志码:A DOI:10.3969/j.issn.1003-9015.2025.02.018

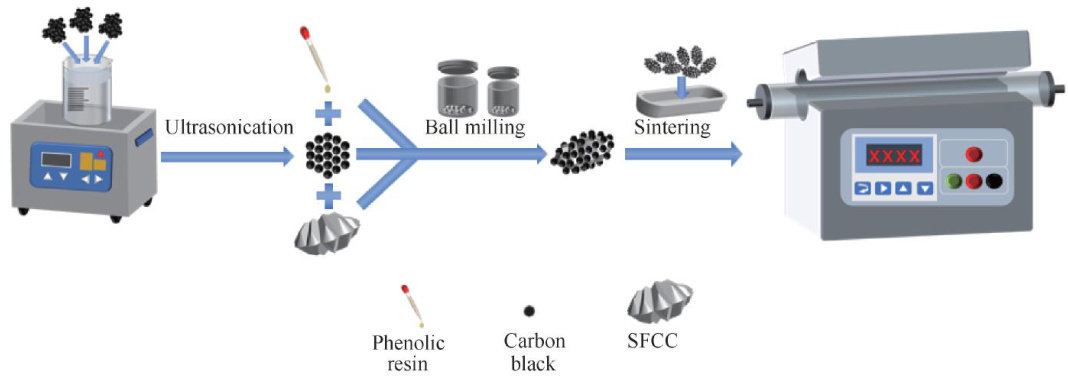

Abstract:In order toachieve high valued reuse of spent fluidized catalyticcracking catalyst(FCC),carbon black particles wereuniformly loaded on thesurface of spent FCC(SFCC)catalyst by high-energyball milling method.The loading amount of carbon black was regulated,after which the ceramic/carbon composites were obtained by high temperature sintering.X-ray diffaction,scanning electron microscope and vector network analyzer were used to characterize the ceramic/carbon composites.Efects of carbon black loading on the microwave absorption propertiesof theceramic/carbon composites was investigated.Theresults showthat the ceramic matrix generatedafter sintering resulted in composites with excellnt impedance matching,while the carbon black particles are uniformly dispersed inthe composite matrix to formaconductive network,which provides thecomposites with dielectric loss.The ceramic/carbon composites prepared by sintering at 1 300qC had excellent microwave absorption properties when the carbon black loading was 8% (Mass fraction).The minimum reflection loss value reached -49.93 dB when the matched thickness was 3.1mm ,and the maximum effective absorption bandwidth reached 5.2 GHz when the matched thickness was 2.0mm .This is mainly attributed to the polarization effect,conductive loss and good impedance matching inside the composites.In addition,the heavy metals contained in the spent catalyst are converted to spinel after sintering and immobilize in the composite material,which realizes the harmless treatment of the SFCC catalyst.

Key words: SFCC catalyst; carbon black; sintering; ceramic/carbon; microwave absorption property

1前言

无线电子设备在给生活带来诸多便利的同时,过量的电磁波辐射也给生活带来了不良的影响[1]。(剩余18713字)