基于多目标模型预测控制的感应加热碳热还原过程操作策略分析

打开文本图片集

中图分类号:TQ021.8 文献标志码:A DOI:10.3969/j.issn.1003-9015.2025.02.014

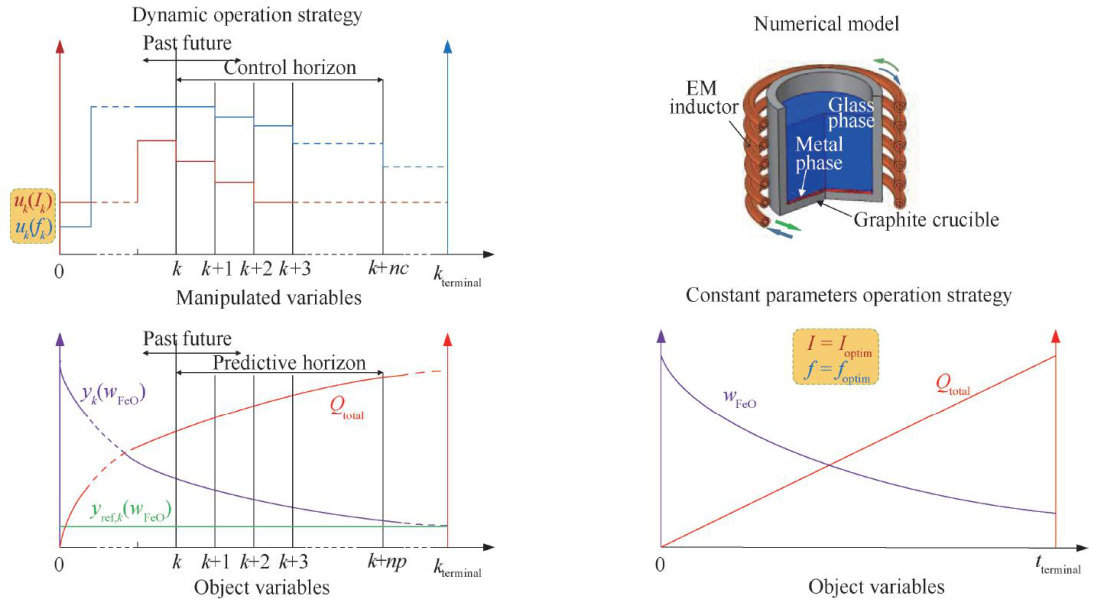

Abstract: To reduce energy consumption and control residual iron oxide in the induction heating carbothermal reduction processes of aluminosilicate solid wastes,an operation strategy based on multi-objective model predictive control was proposed to optimize the current and frequency with the objectives of reducing the total energy consumptionand increasing the reductionrate of iron oxide in the melt.Bycombining weights of diffrent objectives,effects ofoperating parameters on diferent objectives and the value basis of operating variables in predictive control were analyzed.Resultsshow that for thereaction system with high reduction target,the frequency increases after the melting time reaches upper limit in prior the increase of the current.Compared with the constant parameter operation strategyto achieve the same reduction degree,the model predictive control operation strategy can further reduce energy consumption.Higher reduction degree ina longer alowable melting duration results in better energy conservation. In the case studies,when the target reduction degree is less than 87.0% with a short melting duration,the advantage of themodel predictive control operation strategy is not significant in the aspect ofenergy conservation. The optimized constant parameter operation strategy needs to be adopted. The results can provide analysis and calculation basis for multi-objectiveoptimization operation strategy of induction heating carbon thermal reduction process.

ey words:smelting reduction;multi-objective optimization;model predictive control;dynamic operating strateg

1前言

冶金、采矿等行业产生的大宗铝硅酸盐固废中往往含有较多的铁氧化物杂质。(剩余16129字)