S31008不锈钢焊接全流程质控技术优化研究

打开文本图片集

Abstract:Todressthedefectssuchashotcracks,Ophase precipitation,andintergranularcorosionthatareprone tooccurinthe welding jointsofeatresistantusteniticstainlessstelS38,thisppersystematicalstudedteweldingperfoanceadhigh temperaturefailuremechanismofthisstainlessteeltroughtheoptimizeddesignofthematchingofweldingmaterials,thecontrolof gradientheatinput,ndthedynamiccoolingprocessBasedonorthogonaltestsndstandardtests,thepaperrevealedthehbitory effectoftecoordnatedontrolofeatiputandinterlaertempratureonthprecipiatonbehaviorofarbdesndonstructefullprocessqualitycontrolsystemcovering pre-welding purificationtreatment,processparametermonitoring,andpost-welding microstructureoptiization.Theresultsshowtattheoptimizedprocesscanincreasetheigtemperaturestrengthoftheweldingjoint to 92% of that of the base metal and reduce the intergranular corrosion rate by 45% , providing a standardized solution for the welding andmanufacturingofhigh-temperature pressre-bearing equipmentsuchaspetrochemicalreactorsandnuclearsteamgenerators.

Keywords:S31Oo8 stainless steel; weldability; high-temperature tensile creep test; heat inputcontrol

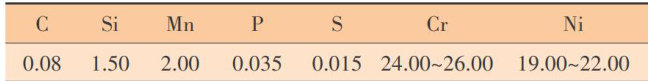

S31008(06Cr25Ni20)是一种高铬高镍耐热型奥氏体不锈钢,凭借其优异的高温强度( 1150∘C 下抗氧化性达 0.12mg⋅cm-2⋅h-1. )与抗蠕变性能0 700∘C/70MPa 断裂时间 >100h ),在石油化工、锅炉制造、航空业及其他高温、氧化环境中得到了广泛应用。(剩余4208字)