轧钢双蓄热式加热炉煤气反吹系统优化调整分析与研究

打开文本图片集

NALYSISANDRESEARCHONOPTIMIZATIONANDADJUSTMENTOFGASBACKBLOWINGSYSTEMFORDOUBLEREGENERATIVEREHEATINGFURNACEINSTEELROLLING

Wang Xuewu (Shougang Group Qian'an Iron and Steel Company Qian'an ,China)

Abstract:This paper addresses the problems of polution and energy waste in the regenerative reheating furnaces for steelrolling,where the frequentcommutation leads to the discharge of gas in the pipelines along with theflue gas, resulting in an average carbon monoxide (CO) emission concentration of approximately 15000mg/m3 . Against the policy backdrop ofthe Grade A performance evaluation for iron and steel enterprisesand the implementation of CO environmental protection tax in some regions,this studytakes thereheating furnaces equipped with soot backblowing devices in Hebei Province and other areas—where CO emisions remain relatively high—as the research objects. Throughon-site investigationof theoperation dataofregenerativereheating furnaces for steel rolling inmultiple iron and steel enterprises (EnterprisesA,B,C,D,E,andF),researchon CO emissionreductionand control technologies is carried out.

Key words:regenerative type; reheating furnace; gas backblowing

0前言

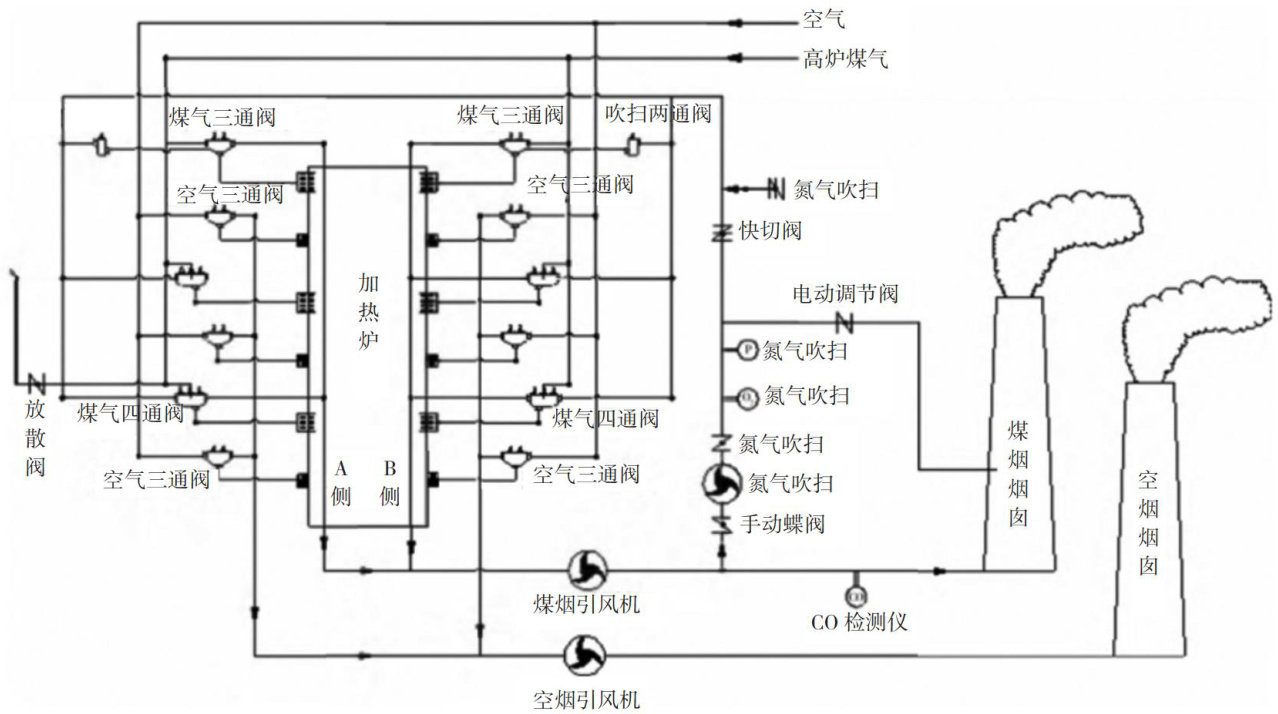

钢铁企业轧钢双蓄热式加热炉在工作过程中交替频繁换向,每次换向阀切换,一组(侧)烧嘴由燃烧状态转变成排烟状态时,换向阀到蓄热式烧嘴之间管道内的煤气就会随排烟系统抽走造成环境污染。(剩余3439字)