7020铝合金焊接工艺对焊接残余应力与应变的影响研究

打开文本图片集

关键词:7020铝合金;焊接仿真;预热;热源输入;残余应力应变

中图分类号:TH162 文献标志码:A 文章编号:1003-5168(2025)11-0024-04

DOI:10.19968/j.cnki.hnkj.1003-5168.2025.11.006

Research on the Influence of 7O2O Aluminum Alloy Welding Process on WeldingResidualStressandStrain

ZHANG Huayan (Shanghai-Donghu MachineryFactory,Shanghai2O19oo,China)

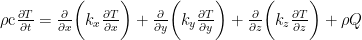

Abstract: [Purposes] This study aims to investigate the effects of different welding process parameters on residual stress and residual strain in the welding repair of 7O2O aluminum alloy plates, with the goal of determining optimal heat input parameters to optimize welding quality.[Methods]A welding simulation model based on the double-elipsoidal heat source model was established using inert gas-shielded laser welding technology.Finite element analysis was employed to simulate the dynamic thermo一 mechanical coupling process. Multiple experimental parameters,including welding current ( 200~240 (20 A), voltage ( 20~24 V),and initial workpiece temperature (20~300∘C ),were examinedto analyze their effects on temperature distribution,residual stress,and residual strain.[Findings] The simulation results indicate that when the welding current was 240 A and the voltage was 24 V,both residual stress and strain were minimized.When the preheating temperature is 200∘C ,the residual stress and strain can be significantly reduced,but when the temperature rises to 300∘ C, the residual strain increases instead. Additionally,the increase in power leads toa rise in the maximum temperature,but hasa limited impacton residual stress.[Conclusions] The optimized welding parameters (240 A current,24 V voltage) combined with 200∘C preheating effectively controlled residual stress and strain,providing a theoretical basisfor the welding repair process of 7O2O aluminum alloy plates. Keywords: 7O2O aluminum aloy; welding simulation; preheating; heat sourse input; residual stress-strain

0 引言

焊接变形与残余应力形成机理的研究发现,铝合金焊接过程中的热-力耦合效应是引发焊接部位变形与残余应力的关键因素。(剩余5782字)