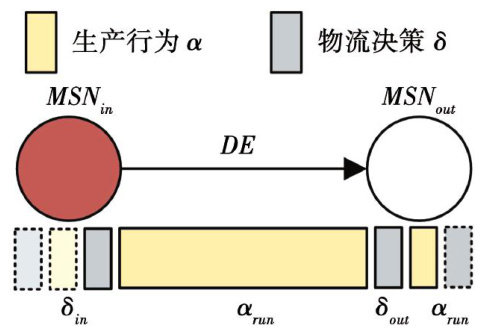

物料流元模型驱动的离散车间生产仿真研究

打开文本图片集

关键词:离散制造车间;物料流元模型;建模与仿真;七要素建模理论;进程交互法DOI:10.15938/j. jhust.2025.02.001中图分类号:TP391.9 文献标志码:A 文章编号:1007-2683(2025)02-0001-10

Abstract:Withtheincreasingcomplexityanddiversityof the productionprocessinmodern manufacturing,thecompositioof the manufacturingsystemforthedemandofmulti-speciessmallotproductionismorecomplexandthematerialfowisirgular,which makesitdificult toensuretheflexibilityofthematerialflowmodelingandtheaccuracyofthesimulationprocess.Forthisason,a methodbasedonMaterialFlowMetaModel(MFMM)isproposed tosimulatetheproductionprocessofthediscretemanufacturing plant.Basedontheseven-element(SE)modeling theory,theMFMMmodelisfurtherdefinedtodescribethematerialflowandcontrol mechanism;aprocess interactionsimulationalgorithmbasedontheMFMMisdesignedtosimulatethematerialflowprocess;a corresponding prototypesystemisdeveloped tosupporttheproposedmethod.Anintellgentmanufacturing workshopisusedasan exampletovalidatetheproposed method.TheexperimentalresultsshowthatcomparedwithFlexsim,theproposedmethodachieves 99. 8% simulationaccuracyonaverage,andhascertain advantages in theflexibilityof material flow modeling,which proves its effectiveness and practicability in complex manufacturing environments.

Keywords:discrete manufacturing plant;material flow meta model;modelingand simulation;seven-element modeling theory process interaction approach

0引言

在全球制造业竞争加剧且技术快速发展的背景下,生产过程的复杂性不断增加,尤其是在多品种、小批量的离散制造车间中,这些复杂性导致车间物料流动频繁且动态的变化,为生产系统的效率和灵活性带来了巨大挑战[1]。(剩余12575字)