非滑道区域建造导管架的精度控制方法分析

打开文本图片集

中图分类号:TE54 文献标志码:A

AnalysisofPrecision Control Methods forJacket Construction in Non-Slipway Area

ZHAO Pengzhi, SHEN Chao, DING Shixing,LIU Dongzhao, HUANG Litao(COOEC-Fluor Heavy Industries CO.,Ltd., Zhuhai , China)

Abstract: Jacket construction in non-slipway areas ofers advantages such as reduced costs and improved site utilization.This paper elaborates on key dimensional control techniques and practical experience.Pre-deformation allowances are determined throughballasting testdata analysis;adjustment measures for horizontal out-of-tolerance conditions caused bydifferential settement are summarized; welding sequences for wellhead support pipe interfaces are defined; and an optimal centerline establishment method for wellhead modules is proposed.These approaches provide references for precision control in non-slipway jacket construction.

Key Words: non-slipway area; ballasting test; differential settlement;welding sequence; piece centerline

1 引言

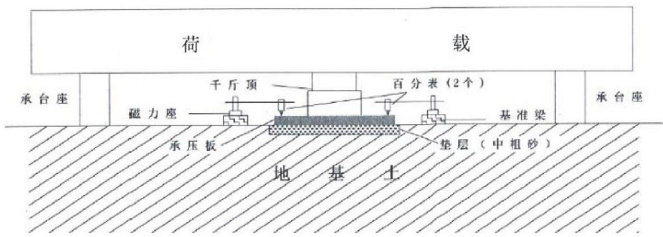

随着国家加大对海洋油气资源开发的力度,海洋油气导管架建造需求日渐增加,众所周知的是此类海洋油气导管架尺寸小则百米大则数百米[1,该结构尺寸长重量大是其显著的特点,因此通常是在滑道上建造,然而由于滑道资源的饱和和导管架订单的增加,为拓展发展渠道并加之经济性的考虑,当下行业内正在打破固有观念,采用非滑道场地进行建造,由此使得非滑道导管架建造的尺寸控制技术显得尤为重要,在此过程中不仅面临着导管架整体不均匀沉降所带来的水平度问题,更要考虑不均匀沉降对包括井口同心度、头部、尾部裙装等尺寸的严重干涉和影响,且在建造吊装定位过程中,更是要考虑其现有的尺寸状态和将来的变化趋势,才能成功的将其精度把控在合理的公差范围之内。(剩余4274字)