铜纳米颗粒改善润滑摩擦特性在注塑/冲压模具中的应用

打开文本图片集

中图分类号:TG76;TQ320.662 文献标志码:B

Applicationofcopper nanoparticles toimprovelubrication friction characteristics in injection/stamping molds

LIANG Bei1, SUN Lirong², XIAO Guohua’,LU Yunxiang³,LI Xiangfen³, YANG Shaozeng'

(1. School of Mechanical and Electrical Engineering,Zhejiang Business and Technology Institute,Ningbo 315O12,Zhejiang,China; 2. Ninghai County First Vocational High School,Ningbo 3156Oo,Zhejiang,China; 3. Ningbo Huabao Intelligent Technology Co. Ltd.,Ningbo 3156Oo,Zhejiang,China)

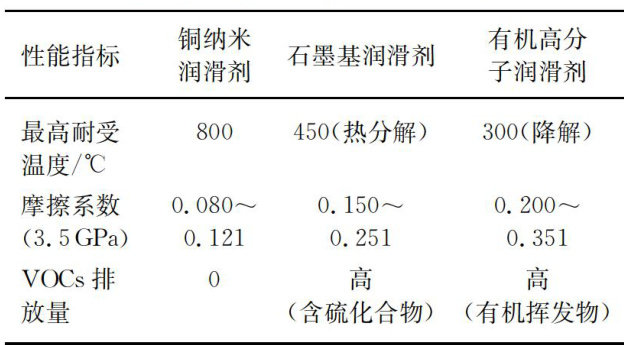

Abstract: Copper nanoparticles (Cu NPs) demonstrate remarkable advantages in mold lubrication due to their unique physicochemical properties. This review systematically summarizes the mechanisms,performance optimization, and practical applications of Cu NPs in injection/ stamping molds. Studies reveal that Cu NPs enhance high-temperature stability (withstanding 800∘C )and environmental performance ( 62% reduction in carbon footprint) through dynamic lubricating film formation (friction coefficient as low as 0.07-0.12) , surface modification synergy (extreme pressure load capacity up to 3.5GPa ),and self-healing mechanisms (23%-27% reduction in wear scar diameter)12.Experimental data indicate that lubricants containing O. 6% Cu NPs extend mold lifespan by 80%-150% and reduce maintenance costs by 30%29 . However,challenges such as high production costs (3 -5 times conventional lubricants) and insuficient long-term stability (>15% performance decay per 1000 hours) hinder large-scale applications.Future research should focus on green synthesis (e.g.,plasma-assisted reduction),composite materials(e.g. , Cu@Ti3C2 ),and intelligent lubrication systems ((response time <50ms ) to overcome these barriers359. This work provides theoretical and technical insights for industrializing Cu NPs in mold lubrication.

Key words:copper nanoparticles(Cu NPs);mold lubrication; dynamic lubricating film;surface modification; self-healing; green manufacturing

0 引言

摩擦与磨损是机械加工中的核心问题,全球每年因摩擦导致的能源损耗高达数万亿美元。(剩余16052字)