基于有限元仿真的铝合金轮毂挤压工艺参数优化

打开文本图片集

中图分类号:TG376.1 文献标志码:A

文章编号:1001-4934(2025)03-0080-14

Optimization of aluminum alloy wheel extrusion process parameters based on finite element simulation

JIN Zefa',YE Zhang²,HE Lijun1,ZHANGYijie²

(1. School of Materialsand New Energy,NingxiaUniversity,Yinchuan 75oo21,Ningxia,China;2. New Materials Research Institute,Dongliang AluminumCo.Ltd.,Huzhou 313ooo,Zhejiang,China)

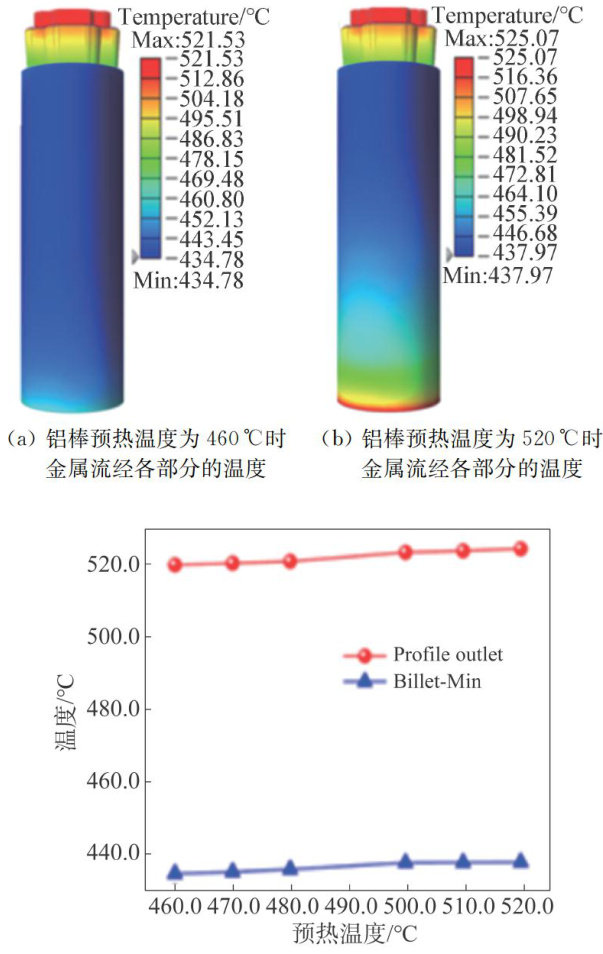

Abstract:This article uses finite element method to explore the effects of four main extrusion process parameters, namely aluminum rod preheating temperature, mold’preheating temperature,extrusion cylinder temperature,and extrusion speed,on the outlet temperature of wheel hub profiles and the temperature of aluminum rods during the extrusion process; The optimal extrusion process parameters for wheel hub profiles were determined through orthogonal experiments and actual extrusion production conditions, which are: extrusion speed of 7. 0mm/s ,aluminum rod preheating temperature of 500. 0°C , mold preheating temperature of 450. 0°C ,and extrusion cylinder temperature of 440. 0°C ;Finally,the mechanical properties of the wheel hub profiles produced with the initial and optimal extrusion parameters were analyzed from two aspects: grain size and precipitate phase,and the influence of microstructure under different extrusion process parameters on the final performance was analyzed. The results show that the influence of extrusion process parameters on the grain size of profiles and the influence of grain size on the mechanical properties of extruded profiles are minimal. The outlet temperature of the profile significantly affects the aging strengthening effect and the mechanical properties of the profile. The mechanical properties of the extruded profile are mainly determined by the number and size of precipitates. The smaller and more precipitates,the higher the strength.

Key words:hot extrusion; finite element simulation; orthogonal experiment; aluminum alloy; profile outlet temperature

0 引言

6082铝合金是6系铝合金中强度较高的一种,由于其良好的耐腐蚀性、导热性、挤压加工和可焊接性,被广泛应用于交通运输、航空航天、建筑结构件和光学仪器领域[1]。(剩余16041字)