基于LFT-D复合材料的建筑模具成型优化研究

打开文本图片集

中图分类号:TP089 文献标志码:A

Optimization of the forming process of architectural molds based onLFT-D compositematerials

QIUShixiong,CHENGLianji,QIUWei,LIHengbin,DUWenyou (Southwest Communications Construction Group Co. Ltd.,Kunming 65O5Oo,Yunnan China)

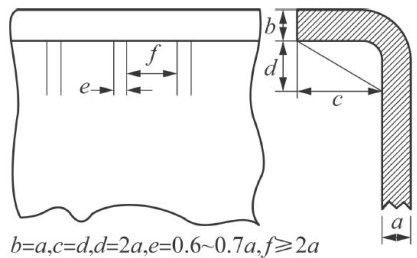

Abstract: The stability of construction projects directly affects the overall quality of the project. In order to improve the stability of the construction project structure, this paper takes the construction formwork as the research object and uses PA6+GF30% LFT -D composite material to design the mold structure and cooling system. By analyzing the diameter of the cooling pipe,calculating the cooling time and the distance between the pipe and the cavity surface,the mold process parameters are optimized. The results show that the process parameter combination of mold temperature 45∘C ,melt temperature 215∘C ,injection time 8s ,holding time 1O seconds and holding pressure 80MPa is the optimal solution. In the solid contact surface, the heat exchange of the cooling solid contact surface shows a downward trend,and the higher the coolant fluid temperature, the lower the heat exchange. In the liquid-solid contact surface,with the increase of the coolant temperature,the heat exchange gradually decreases,and when the coolant temperature is 40°C ,the heat exchange shows a slow upward trend. In addition,the tensile strength, bending strength and impact toughness of the mold casting are 203MPa , 269MPa and 32.5kJ/m-2 ,respectively. In the casting procedure,the pouring time,shear rate and filling rate were 8.74s , 4×105s-1 and 98.44% respectively. The optimized mold forming process showed the best effect.

Key words: building engineering structure; LFT-D composite material; material mold; mold forming; process optimization

0 引言

随着社会经济的快速发展,建筑行业对质量、效率以及可持续发展的要求不断提高。(剩余11965字)