基于工程力学的模具结构优化设计与应力研究

打开文本图片集

中图分类号:TP926 文献标志码:A

Die structure optimization design and stress research based on engineering mechanics

LIDezheng,CAILili,DUANZhao,LI Xiaowen (Southwest Communications Construction Group Co. Ltd. , Kunming 65o50o,Yunnan,China)

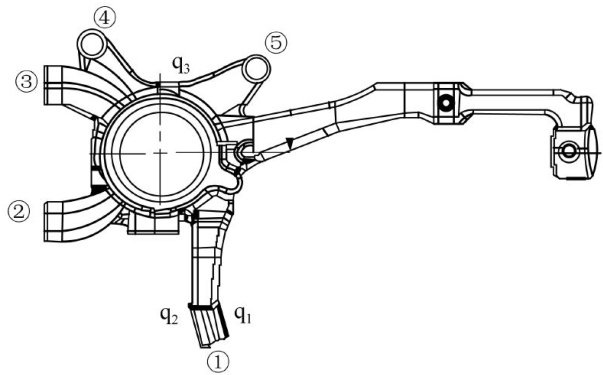

Abstract: This paper focuses on the metal steering knuckle of an automobile, proposing a hot forging process based on the analysis of the steering knuckle's structure, materials,and process. By calculating the extrusion pressures in the mold cavity for both the mold entrance casting and the straight cylindrical casting, the internal deformation due to external loads acting on the entire casting in the mold is determined. Using finite element software,the hot forging process of the mold is simulated, revealing a gap defect in the longest branch of the mold. To address this defect,a resistance wall structure is designed within the mold,aiming to control the direction and speed of the molten material flow, thereby preventing gap defects in the casting. The results show that, compared to the original design,the pre-forging load increased by 16.09% ,and the final forging load increased by 11.94% . The optimized mold demonstrates the best performance among all molds,with injection time,shear rate,and filling rate of 10.13s , 5×105s-1 ,and 97.14% , respectively. By adjusting the slope and gap levels of the resistance wall, significant improvements in mold wear were achieved.

Key words: die structure; hot forging of steering knuckle; external load; finite element software;shear rate

0 引言

在我国工业技术快速发展过程中,模具作为基础生产设备,具有重要地位。(剩余10081字)