反压注塑发泡成型模具优化设计

打开文本图片集

中图分类号:TG76 文献标志码:A

文章编号:1001-4934(2025)03-0048-06

Optimization design of counter-pressure injection foam molding mold

FANG Yongjie, GAO Yehan, LI Jinyue, LIU Saike, XUE Ningjun,LUO Bihui, CHEN Chen(Ningbo Fangzheng Automobile Mould Co. Ltd.,Ningbo 3156Oo, Zhejiang,China)

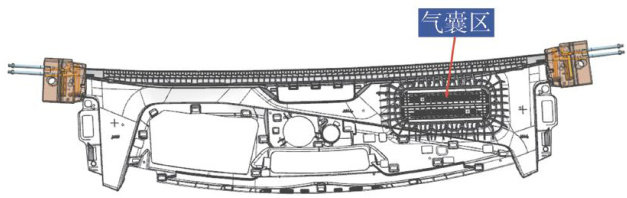

Abstract: This article proposes a set of counter-pressure injection foaming molding process and mold design optimization solutions to solve the manufacturing problems of automobile instrument panel injection molded parts with complex structures and high performance requirements. Through the pre-settng mesh cloth by the manipulator and the staged back pressure injection molding foaming process,the airbag area is injected first under the condition of 1mm mold gap,and the mechanical properties of the airbag area of the product are improved by the mesh cloth reinforcement effect and pressure gradient control. In view of the control requirements of the non-foaming area,a pneumatic ejector and cylinder drive spring block composite system is developed,and anti-foaming control is achieved through dynamic pressure compensation. According to the characteristics of the mold structure, different water channels are designed on both sides of the mold,and 3D printing water channels and beryllum copper inserts are designed in the airbag area to ensure the consistency of the overall cooling of the injection molded parts. Through the above mold process optimization and mold structure design, high-quality and high-performance molding of complex parts of automobile instrument panels is achieved.

Key words: injection foam molding;automobile instrument panel; injection molding process optimization;mold structure design

0 引言

随着汽车、航空航天、电子等行业对高性能、轻量化产品的需求不断增加,新型材料不断涌现,如高性能工程塑料、纤维增强复合材料等[1-3]。(剩余6058字)