锥形塑料保持架仿真模拟优化及模具设计

打开文本图片集

中图分类号:TH122 文献标志码:A

Tapered Plastic CageSimulation Optimization and Mold Design

LIN Caimei',ZENG Xiaoan',YE Songwen²,LIU Haiqing

(1. Luoding Polytechnic, Guangdong Yunfu 5272Oo, China; 2. Guangdong Faner Aromaproduct Co.Ltd:,Guangzhou 51o54o,Guangdong China)

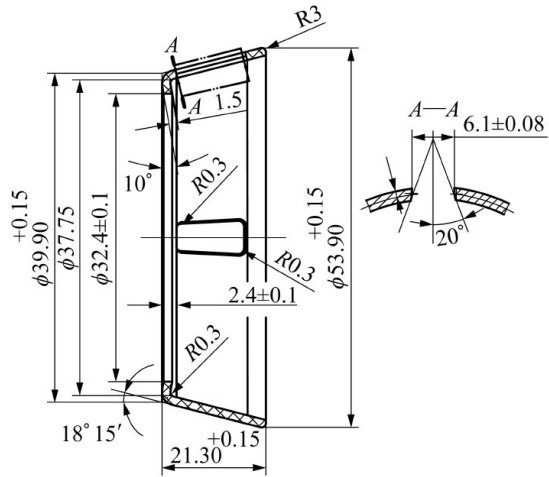

Abstract:A case study of Cage design optimization and injection mold design is presented through research on force analysis and mold design aspects of plastic cages in high-speed bearings. Using computer-aided software to analyze the force of polyamide-66 (PA66) plastics with 10% , 20% , 30% and 35% glass fiber mass fraction,respectively. The results show that square pocket hole cage glass fiber mass fraction of 35% ,the maximum equivalent force of PA665.641MPa ,compared with the glass fiber mass fraction of 10% reduced by 16.5% The maximum equivalent force of 30% and 35% glass fiber mass fraction is close to the maximum equivalent force. Glass fiber mass fraction of 30% ,the maximum deformation of PA66 is the smallest 0.00208mm ,compared with the glass fiber mass fraction of 10% and 20% of the significant reduction of more than 50% ,and the glass fiber mass fraction of 35% of the maximum deformation is closer. By comparing the maximum displacement deformation and equivalent force, The results show that under the same working conditions, the maximum deformation and equivalent force of PA66 - GF3O cage are minimized, thus obtaining the best material PA66 - GF3o. Design a point gate double parting surface guide pillar-guided injection mold,the structure of a mold with two cavities,each cavity cage were designed by four side core slider,a convex inserts mold and a cavity inserts mold molding, each slider is molded three square pocket holes, to solve the cavity slider there is mutual interference and difficult to equal parts design and other problems, simplify the mold structure,and so on. This solves the problems of mutual interference of cavity sliders and the difficulty of equal division design,and simplifies the mold structure. The research results can provide certain reference value for the Material selection of bearing cage and design of injection mold with lateral parting and core pulling mechanism under high speed working condition.

Key words:plastic cage; glass fiber; force analysis; one mold two cavities;mold structure

0 引言

保持架作为高速轴承的分隔体引导滚动体运动的核心部件,对提高轴承的稳定性、使用效率及使用寿命至关重要[1-2]。(剩余8232字)