基于ANSYS的超声振动辅助无钉铆接系统优化设计

打开文本图片集

中图分类号:TG156 文献标志码:A

Optimization and design of ultrasonic vibration-assisted clinching system based on ANSYS

XU Kai, WANG Xingxing* , PAN Li, CHEN Xingxiang, LUO Ying,GAO Shanjie,SONG Xingyu, LU Heng (School of Mechanical and Electrical Engineering, Suqian College,Suqian 2238Oo,Jiangsu, China)

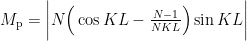

Abstract: In this paper, a system of ultrasonic vibration-assisted clinching system was developed to improve the connection structural strength of carbon fiber reinforced composite and metal. First,the dimensions of the core parts such as the transducer,amplitude lever,and tool head are calculated based on the theoretical formula,and then the structure design and modeling of the core parts are carried out. Second, ANSYS is used to conduct a simulation analysis of the core parts and their overall structure. The modes analysis of the amplitude transformer,tool head,and overall structure are15158,14926,and 15156Hz respectively,and the errors of 15 kHz for the design requirement are 1.05% , 0.49% ,and 1.04% respectively. Then,the prediction model of the structure size parameters of the amplitude transformer with different frequencies is established. The prediction error is less than 1% ,but the prediction accuracy decreases with the increase in the prediction frequency. Finally, a system of ultrasonic vibration-assisted clinching system with a resonant frequency of 15.21kHz and an amplitude range of 5~45μm at the working end position of the tool head is developed.

Key words:ultrasonic vibration-assisted clinching system; response surface methodology; amplitude transformer;finite element analysis

0 引言

车身结构材料的轻量化、节能、环保以及安全技术水平成为我国新能源汽车行业发展的方向。(剩余9242字)